In recent years, the demand for thick plastic sheets has witnessed a significant surge, driven by their versatility and application across various industries. According to a report by Grand View Research, the global plastic sheets market is expected to reach USD 40 billion by 2025, with thick plastic sheets representing a substantial segment due to their durability and effectiveness in numerous applications. From construction to packaging, the utilization of thick plastic sheets has proven to be invaluable in enhancing operational efficiency and reducing material costs.

As businesses and consumers increasingly seek sustainable and cost-effective solutions, thick plastic sheets have emerged as a go-to material. They are not only resistant to moisture and chemicals but also offer excellent insulation properties. The American Plastics Council projects that the growth of the thick plastic sheets market will be driven by innovations in manufacturing processes and materials, which will further broaden their applications. This article presents the top 10 uses for thick plastic sheets in 2025, showcasing their ability to meet diverse needs and highlighting their role in promoting efficiency and sustainability across various sectors.

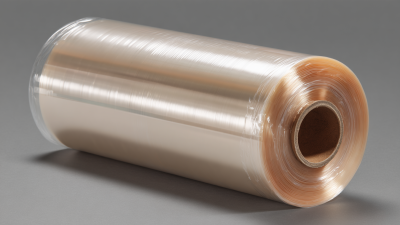

In 2025, the demand for innovative packaging solutions utilizing thick plastic sheets is expected to surge, addressing the growing need for sustainable and efficient materials. As industries increasingly focus on environmental responsibility, thick plastic sheets offer a versatile alternative for various packaging applications. They provide durability and protection for products while also being recyclable, aligning with eco-friendly initiatives. This shift towards sustainable packaging is crucial as the global molded pulp packaging market is projected to expand significantly, from $5.78 billion in 2025 to $9.43 billion by 2032, indicating a strong consumer preference for environmentally responsible options.

The versatility of thick plastic sheets extends beyond traditional packaging. They can be customized for multiple purposes, including storage solutions, protective barriers, and even display materials. Industries ranging from food and beverage to electronics are adopting these solutions to enhance product safety and appeal. As innovations continue to emerge, thick plastic sheets will play a critical role in meeting the evolving demands of consumers and businesses alike, solidifying their place within the packaging landscape of the future.

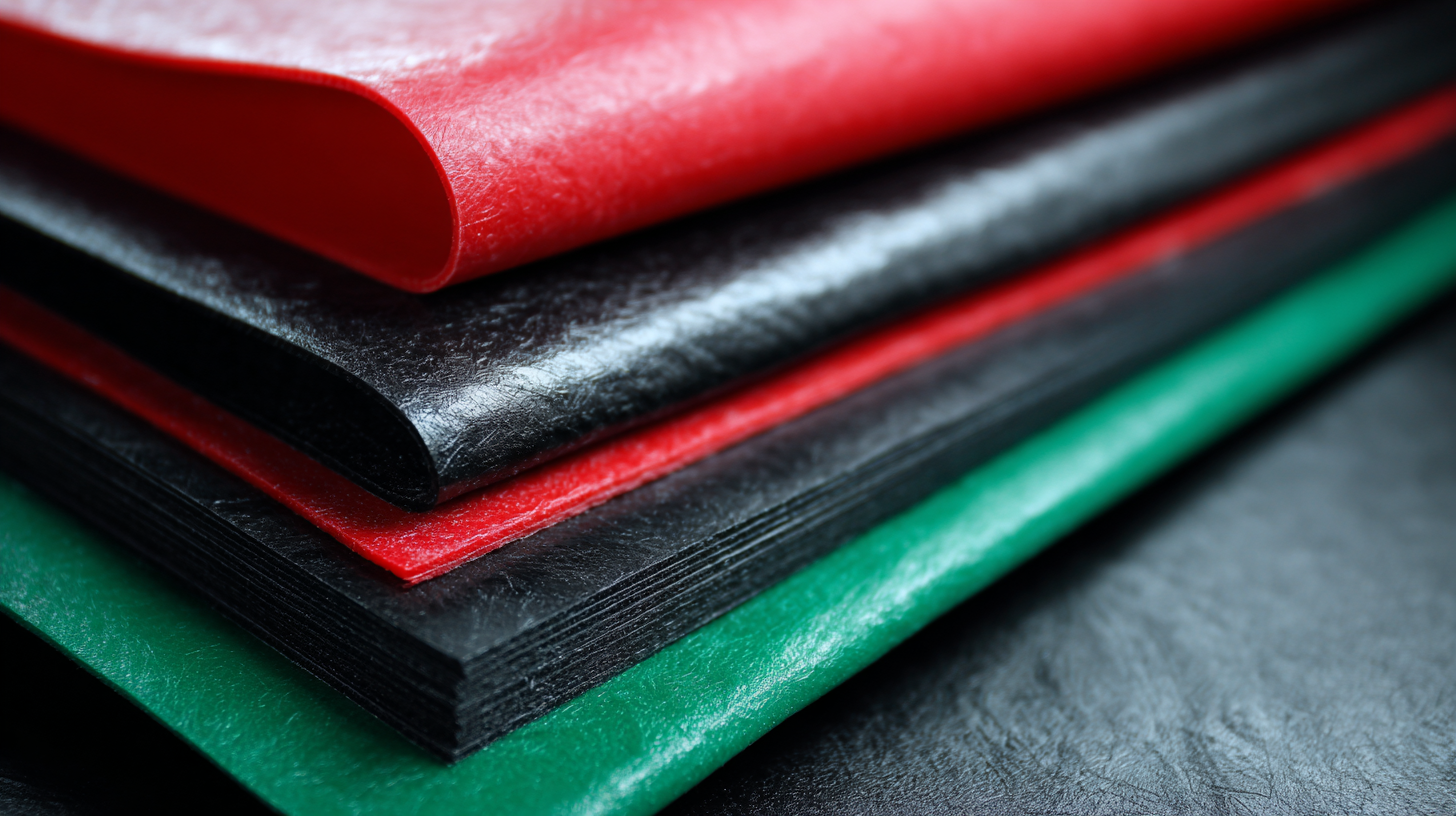

In recent years, the construction industry has seen a significant shift towards the adoption of durable construction materials, particularly thick plastic sheets. These materials offer a lightweight yet robust alternative to traditional building components, which is reflected in the growing demand for them. According to a report from Research and Markets, the global plastic sheets market is projected to reach $35 billion by 2025, highlighting the increasing reliance on these versatile solutions in construction.

Thick plastic sheets, made from materials like polycarbonate and acrylic, provide exceptional durability, weather resistance, and insulation properties. Industry experts emphasize their role in sustainable building practices as they can substantially reduce energy consumption through effective thermal insulation. Furthermore, the National Institute of Building Sciences indicates that using plastic sheets can cut construction waste by up to 30%, making them an eco-friendly option that aligns with green building initiatives. As the industry continues to innovate, plastic sheets are proving to be a transformative solution, bolstering both efficiency and sustainability in modern construction.

Thick plastic sheets, made from materials like polycarbonate and acrylic, provide exceptional durability, weather resistance, and insulation properties. Industry experts emphasize their role in sustainable building practices as they can substantially reduce energy consumption through effective thermal insulation. Furthermore, the National Institute of Building Sciences indicates that using plastic sheets can cut construction waste by up to 30%, making them an eco-friendly option that aligns with green building initiatives. As the industry continues to innovate, plastic sheets are proving to be a transformative solution, bolstering both efficiency and sustainability in modern construction.

Thick plastic sheets are becoming increasingly popular in environmentally conscious industries due to their sustainable applications. The global sustainable plastic packaging market, valued at approximately USD 105.97 billion in 2024, is projected to expand at a compound annual growth rate (CAGR) of 5.43% to reach USD 178.79 billion by 2034. This growth is driven by the rising demand for eco-friendly packaging solutions, where thick plastic sheets play a crucial role in reducing waste and promoting recyclability.

Moreover, as businesses pivot towards greener alternatives, the bioplastic extruder market is on track to reach USD 8.0 billion by 2035, exhibiting a CAGR of 11% during the forecast period. This surge is fueled by heightened environmental awareness and a notable shift towards bioplastics, which often utilize thick plastic sheets in their manufacturing processes. The versatility and durability of thick plastic sheets make them ideal for various sustainable applications, from packaging to construction and beyond, thus positioning them as essential materials in the transition towards eco-friendly practices across multiple industries.

This bar chart illustrates the top 10 uses for thick plastic sheets in 2025, highlighting their versatile applications across various industries. The data reflects usage frequency in units, showcasing the significant demand in construction and packaging sectors.

Thick plastic sheets have emerged as a go-to material for various creative DIY projects, elevating home improvements while offering durability and functionality. One of the most popular uses is creating custom shelving. With sturdy plastic sheets, homeowners can design lightweight and water-resistant shelves that are perfect for garages, gardens, or even craft rooms. These shelves can be cut to size and adorned with decorative elements, ensuring they meet both aesthetic and practical needs.

Another innovative way thick plastic sheets empower DIY enthusiasts is through the construction of garden barriers or raised planters. The sheets can be utilized to create sustainable solutions for gardening, providing protection against pests while helping to retain moisture in the soil. Moreover, they can be easily shaped to fit any garden layout, allowing for personalized designs that enhance any outdoor space. With their versatility, thick plastic sheets are not just materials; they are catalysts for inspiration, encouraging creativity and elevating the home improvement experience.

| Rank | Use Case | Description | Benefits |

|---|---|---|---|

| 1 | Greenhouse Covers | Thick plastic sheets can be used as durable covers for greenhouses. | Enhanced sunlight diffusion and protection from weather elements. |

| 2 | Outdoor Furniture Covers | Protect outdoor furniture from rain and UV rays. | Increased lifespan of furniture and reduced maintenance efforts. |

| 3 | Home Insulation | Used in windows or walls for better insulation. | Lower energy bills and improved comfort. |

| 4 | Storage Bin Liners | Create liners for bins to separate materials. | Easy cleaning and organization. |

| 5 | Project Protection Sheets | Cover floors and furniture during renovation. | Prevents damage and simplifies cleanup. |

| 6 | Aquarium Dividers | Separate fish species within a tank. | Improves habitat control and reduces conflict. |

| 7 | DIY Photo Booth Backdrops | Create fun and colorful backdrops. | Enhances events and parties with creativity. |

| 8 | Windbreaks for Patios | Set up barriers against wind around outdoor areas. | Creates a more comfortable outdoor space. |

| 9 | Raised Garden Beds | Line the bottom of raised beds for drainage. | Improves soil management and plant growth. |

| 10 | Pet Barriers | Restrict pet access to certain areas. | Encourages safety and better organization. |

Thick plastic sheets have emerged as a vital component in various safety equipment applications, thanks to their durability and versatility. These sheets are commonly used in the manufacturing of protective barriers that shield workers from harmful environments. In industrial settings, thick plastic sheets act as shields against chemical spills and flying debris, significantly enhancing occupational safety. Their robust nature allows them to withstand extreme conditions, making them an excellent choice for a range of specialized safety equipment.

In addition to industrial use, thick plastic sheets are also integral to personal protective applications. For instance, they can be transformed into face shields and protective eyewear, offering essential defense for healthcare workers and first responders. With the ongoing need for stringent health protocols, the adoption of thick plastic sheets in crafting face shields has become even more critical. Furthermore, these materials can be shaped into enclosures for hazardous areas, ensuring that individuals are protected from exposure to toxins. Overall, the utilization of thick plastic sheets in safety equipment is a testament to their ability to enhance protection in diverse environments.