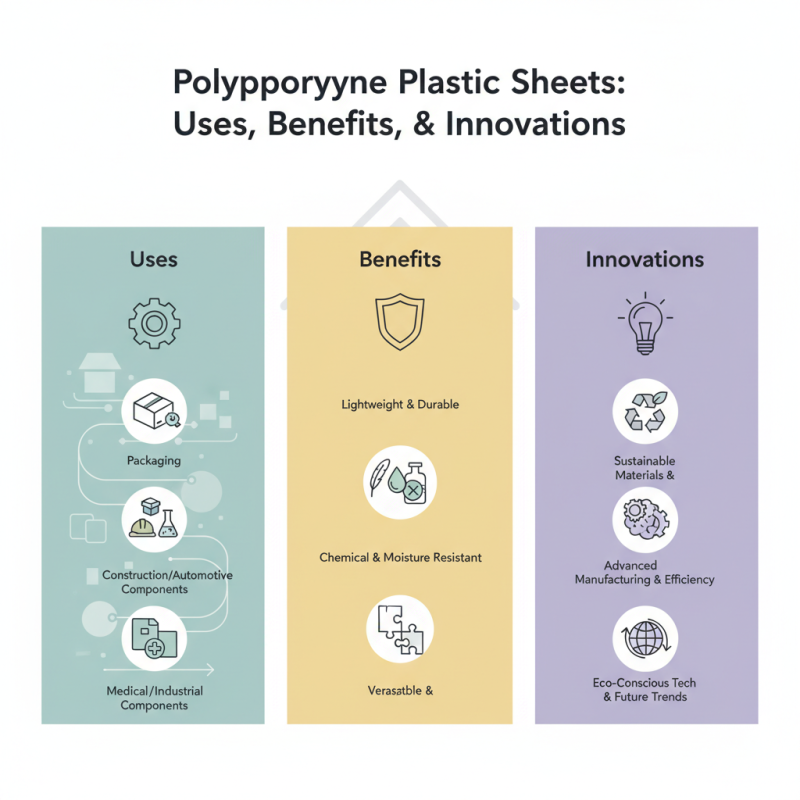

In the realm of modern materials, polypropylene plastic sheets stand out for their versatility and strength. These sheets are widely used across various industries, bringing numerous benefits to manufacturers and consumers alike. From packaging to construction, their applications are diverse and continue to expand.

The evolution of polypropylene plastic sheets has introduced innovative features, enhancing their functionality. They are lightweight yet durable, which makes them ideal for heavy-duty tasks. Their resilience against chemicals and moisture is impressive. Nevertheless, challenges persist in terms of environmental impact and recycling. As consumers become more eco-conscious, the industry must address these concerns.

Exploring the 2026 landscape of polypropylene plastic sheets reveals exciting advancements. New techniques are being developed to improve their sustainability. Innovations continue to pave the way for more efficient usage. However, it prompts reflection on balancing technology and environmental responsibility. Embracing change is essential while remaining mindful of its implications.

Polypropylene plastic sheets are gaining attention across various industries. They are known for their versatility and durability. These sheets boast a lightweight nature and high resistance to chemicals. Their impressive mechanical properties make them suitable for countless applications. Whether in packaging or construction, the uses are extensive.

One of the key features is their moisture resistance. This quality allows them to maintain stability in humid environments. However, some users find that they can be less rigid than other materials. This can limit their use in certain high-stress applications. Additionally, the sheets come in a variety of thicknesses and colors, which adds to their appeal.

Innovation is continually shaping the future of polypropylene sheets. Manufacturers experiment with new processing techniques to enhance their properties. Yet, some challenges remain. For instance, the recycling process can be complex. Awareness of these issues is essential. As industries evolve, so too must the approaches to using polypropylenes effectively.

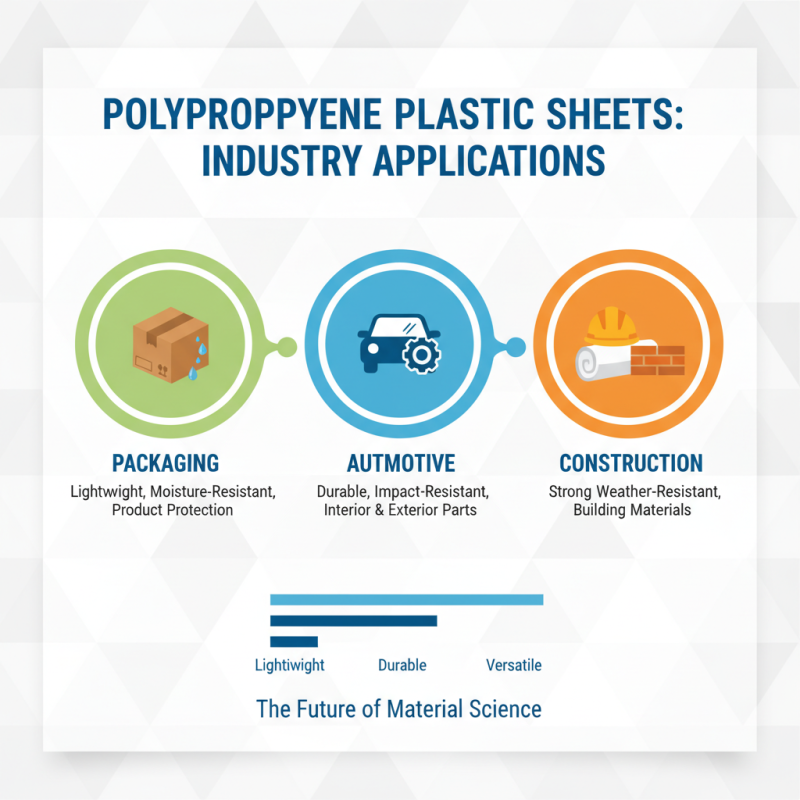

Polypropylene plastic sheets are gaining traction across various industries. They are lightweight and durable. This makes them ideal for packaging, automotive, and construction applications. In packaging, these sheets provide excellent moisture resistance. They keep products secure during transit. In the automotive sector, they are used for interior and exterior parts. Their ability to withstand impact is crucial here.

In construction, polypropylene sheets serve as barriers and covers. They protect surfaces from moisture and dust. However, it's important to select the right thickness for specific applications. Thinner sheets might not provide adequate protection, while thicker ones can be more challenging to work with.

**Tip:** Always consider the environment where these sheets will be used. This can impact their longevity and effectiveness. Also, ensure proper disposal methods are in place. Recycling options exist, but not everyone knows them. An eco-friendly approach can often lead to cost savings too.

Polypropylene plastic sheets have gained popularity due to their numerous advantages over other materials. For instance, they offer excellent chemical resistance, making them ideal for various industrial applications. According to the Plastics Industry Association, polypropylene accounts for approximately 30% of the total plastic production. This statistic highlights its widespread utility and appeal.

One of the key benefits of using polypropylene is its lightweight nature. It is significantly lighter than metals and other plastics, which reduces transportation costs. This can be crucial in industries like packaging, where savings on shipping can enhance profitability. Additionally, its durability limits the need for frequent replacements, resulting in lower long-term costs.

However, challenges exist. Not all polypropylene sheets are created equal; variations in quality can affect performance. Manufacturers must focus on consistency to meet industry standards and consumer expectations. Moreover, while recycling options are improving, the rate of polypropylene recycling remains lower than desired. Stakeholders must push for better waste management solutions to minimize environmental impact. This ongoing dialogue is essential for the future of polypropylene in sustainable practices.

The landscape of polypropylene sheets is evolving rapidly. Recent innovations focus on enhancing durability and versatility. New formulations improve resistance to UV light and chemicals. This advancement enables better performance in outdoor applications and harsh environments. Manufacturers are experimenting with additives that reduce flammability while maintaining flexibility.

Another exciting trend is the incorporation of recycled materials. This shift not only addresses sustainability concerns but also influences pricing. However, the quality of recycled polypropylene can vary significantly. Some products may not meet industry standards. Companies must balance cost and performance to ensure customer satisfaction.

Technological advances also include advanced manufacturing techniques. Techniques like 3D printing allow for more complex designs and shapes. Nevertheless, this presents a challenge; not all facilities can adopt these technologies. The industry must navigate this learning curve and invest in new equipment. This transition could lead to production inconsistencies and quality control issues.

| Application | Benefits | Recent Innovations | Technological Advances |

|---|---|---|---|

| Packaging | Lightweight, moisture-resistant | Biodegradable additives integrated | Enhanced recyclability processes |

| Automotive Components | Durable, impact-resistant | Lightweight composite materials | Injection molding advancements |

| Medical Applications | Chemical resistance, sterilizable | Antimicrobial surface treatments | 3D printing capabilities |

| Construction | UV resistance, lightweight | Insulation improvements | New composite materials for strength |

| Home Goods | Versatile, durable | Colorfast, design innovations | Eco-friendly production techniques |

The market for polypropylene plastic sheets is evolving rapidly. These sheets are lightweight yet durable, making them popular in various industries. They are used in packaging, automotive parts, and construction. As environmental concerns rise, the demand for recyclable materials increases. Innovators are exploring bio-based polypropylene. This could reduce reliance on fossil fuels.

Future trends show a shift toward customization. Manufacturers are creating sheets tailored to specific applications. Enhanced surface properties are becoming essential for many users. These advancements allow for better adhesion in printing and coating processes. However, not all innovations are successful. Some products may not perform as expected. Feedback and testing will be crucial.

Sustainability is a driving force in the industry. Companies are under pressure to develop eco-friendly materials. Biodegradable options are in demand. Yet, the balance between functionality and sustainability remains tricky. Not all biodegradable materials achieve the desired performance. Ongoing research is crucial to find effective solutions. The next few years will shape the future of polypropylene plastic sheets significantly.