The world of ABS plastic is evolving rapidly. As industries adapt to new challenges, ABS plastic materials stand out in numerous applications. This lightweight thermoplastic offers durability and versatility, making it a popular choice across various sectors.

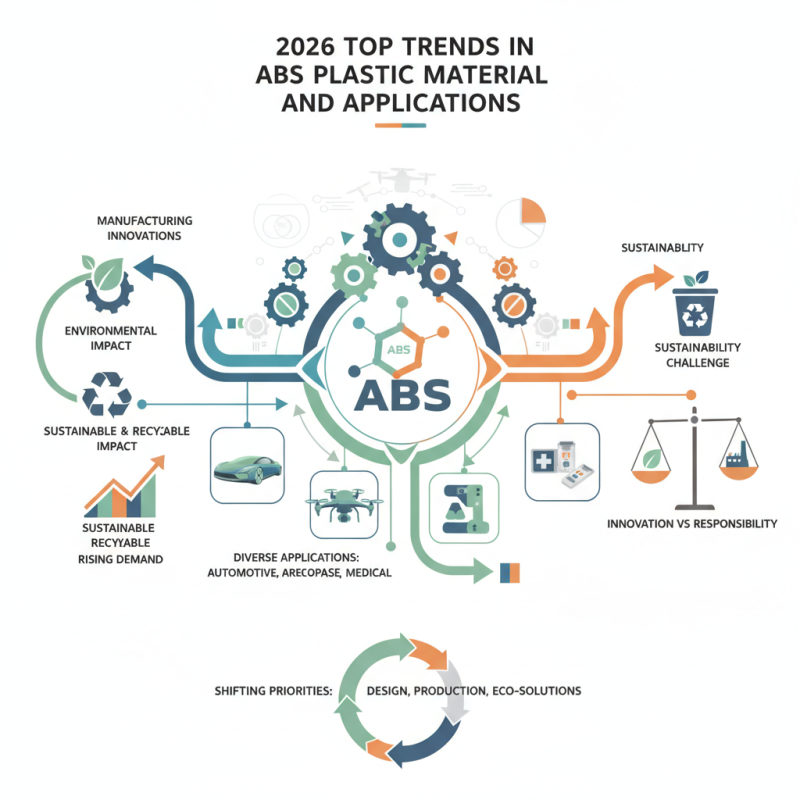

In 2026, we will likely see notable trends shaping the use of ABS plastic. Innovations in manufacturing processes are expected to reduce environmental impact. Meanwhile, the demand for sustainable and recyclable materials will rise. Businesses must reflect on their practices in response to these trends.

However, challenges remain. The reliance on ABS plastic poses questions about sustainability. As companies push for eco-friendly solutions, the industry will need to balance innovation with responsibility. The future of ABS plastic will require thoughtful consideration as priorities shift in design and production.

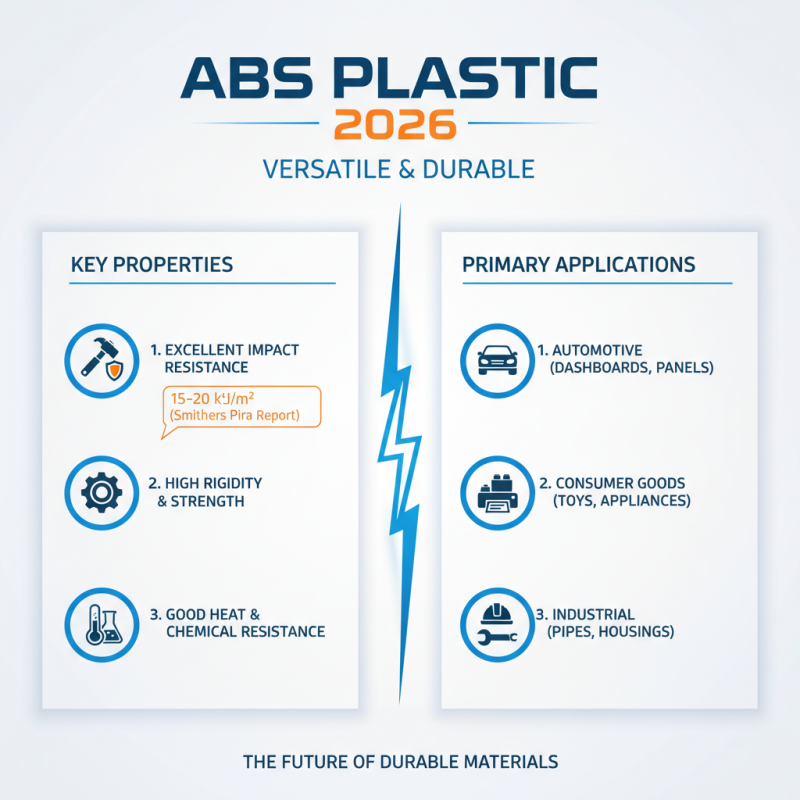

ABS plastic is widely recognized for its unique properties, making it an ideal choice for various applications in 2026. One key characteristic is its excellent impact resistance. According to a report from Smithers Pira, ABS has a notched impact strength of 15-20 kJ/m², which is crucial for industries requiring durable components.

Another significant property of ABS is its superior thermoplasticity. This capability allows for easy molding and reshaping, suitable for complex designs. The global market for thermoplastic materials is expected to grow by over 4% annually. However, the challenge lies in balancing production costs with sustainability. Manufacturers are under pressure to explore bio-based alternatives while maintaining performance.

Additionally, ABS offers good chemical resistance, suitable for automotive and consumer goods. With a heat deflection temperature typically around 80°C, it remains stable under various conditions. Despite its advantages, potential limitations include variability in mechanical properties influenced by polybutadiene content. This inconsistency can impact quality control, urging manufacturers to adopt more precise formulations.

The landscape of ABS plastic manufacturing is evolving rapidly. Innovations are emerging, shaping how this versatile material is produced. One trend is the rise of sustainable practices. Manufacturers are exploring bio-based alternatives to reduce environmental impact. These methods aim to produce materials that are both durable and eco-friendly.

Automation plays a crucial role in modern ABS production. Advanced machinery is being integrated into the manufacturing lines. This increases efficiency and precision in the molding process. However, relying heavily on automation can lead to challenges. Skill gaps may arise among workers who operate sophisticated machines. Training programs are essential to bridge this divide.

Recycling and reusing ABS plastic are gaining traction. Companies are developing techniques to recycle old ABS products into new ones. This not only conserves resources but also lessens waste. Yet, the quality of recycled outputs can vary. Maintaining high standards remains a concern for manufacturers. Embracing these trends can lead to significant improvements, but it also requires careful planning and adjustment.

| Trend | Description | Impact on Manufacturing | Applications |

|---|---|---|---|

| Sustainability | Increase in recycled ABS material usage and eco-friendly production methods. | Reduces waste and energy consumption, enhancing brand reputation. | Consumer products, automotive, and electronics. |

| Advanced Manufacturing Techniques | Integration of 3D printing and injection molding technologies. | Enables rapid prototyping and customization, reducing lead times. | Medical devices, consumer goods, and automotive parts. |

| Improved Mechanical Properties | Enhanced strength, durability, and impact resistance of ABS formulations. | Allows for thinner wall designs while maintaining performance standards. | Structural components in various industries including electronics and automotive. |

| Color and Surface Innovations | New coloring technologies and textures that add aesthetic value. | Increases product appeal leading to higher consumer engagement. | Packaging, household goods, and automotive interior parts. |

| Smart ABS Materials | Incorporation of sensors and connectivity features into ABS materials. | Facilitates the development of smart products and IoT devices. | Electronics, healthcare, and home automation systems. |

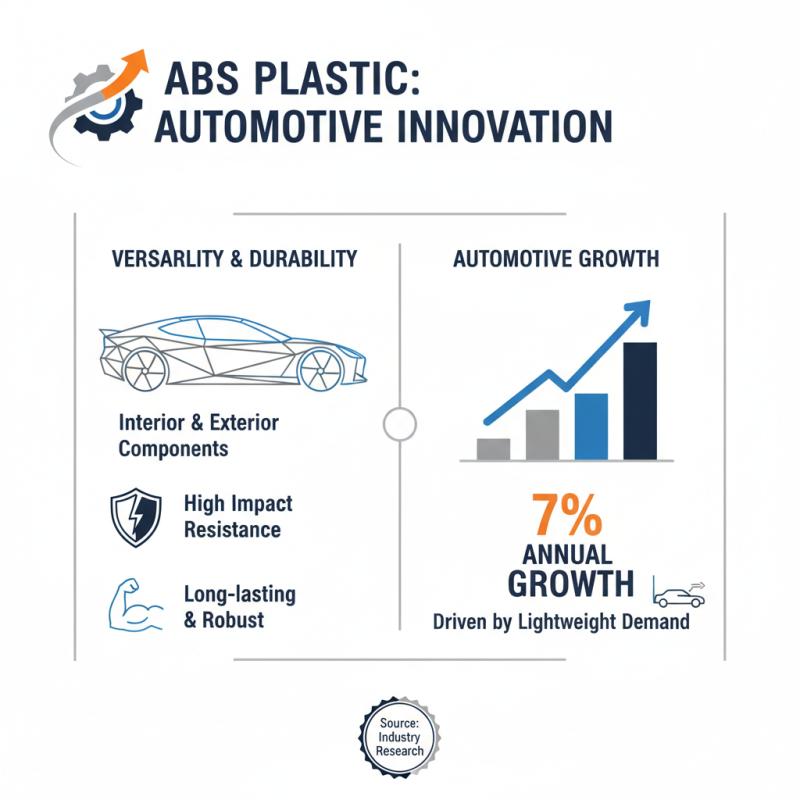

ABS (Acrylonitrile Butadiene Styrene) plastic is gaining traction across various industries. Its versatility is truly remarkable. The automotive sector has adopted ABS for interior and exterior components. It offers durability and impact resistance. Research shows the automotive application is projected to grow at a rate of 7% annually, driven by demand for lightweight materials.

In the electronics industry, ABS is pivotal in housings and components. Its ease of molding allows for intricate designs. According to a recent report, the electronics sector accounts for nearly 40% of ABS consumption globally. Yet, some products may not fully utilize ABS's potential for sustainability. Exploring biocomposite options can lead to innovative solutions.

**Tips:** Explore recycling methods for ABS. It's crucial to reduce waste and promote sustainability. Consider designs that optimize material usage. Small changes can make a big impact. The construction industry is also exploring ABS for pipes and fittings due to its resistance to chemicals and moisture. However, the reliance on traditional materials raises concerns about adaptability to innovative solutions. There's still room for improvement in material science and application techniques.

Sustainability is increasingly a priority in ABS plastic production. Traditional methods often involve high energy usage and toxic emissions. New practices are emerging to counter these effects. One significant approach is the integration of renewable energy sources. By using solar or wind power, manufacturers can reduce their carbon footprint. This shift retains efficient output while being kinder to the planet.

Recycling is another critical area. Many ABS plastics can be reprocessed multiple times. This process decreases waste and energy, but challenges remain. Not all facilities are equipped for effective recycling. Additionally, contamination from other materials can hinder quality. It's essential to focus on improving infrastructure to enhance recycling rates.

Bio-based alternatives are gaining traction as well. These materials reduce reliance on fossil fuels. However, the production of bio-based ABS still faces hurdles. Costs and scalability are significant concerns. Striking a balance between innovation and environmental impact requires ongoing evaluation. Sustainable practices in ABS production necessitate a collective commitment from all stakeholders.

The outlook for ABS plastic materials and products in the coming years looks promising. Demand for ABS is expected to grow in various sectors, including automotive, consumer goods, and electronics. This growth is driven by the material's versatility and durability. Manufacturers are leaning towards ABS for its lightweight properties and impact resistance.

Tips for choosing ABS products: Look for items that highlight their recyclability. Sustainability is crucial in today's market. Verify certifications that showcase the material's quality. This ensures you get the best performance.

However, the industry faces challenges. The market dynamics are unpredictable. Fluctuations in raw material prices could impact production costs. Companies must stay agile to adapt to these changes. Additionally, competition in the ABS market is intensifying. This requires continuous innovation and improvement in product offerings. Embracing new technologies will be key to staying relevant.

This chart illustrates the projected percentage growth in various applications of ABS plastic materials over the next few years. The data reflects the increasing demand across different industries, highlighting the versatility and utility of ABS in modern applications.