The global polyethylene plastic market is adapting to emerging sustainability challenges. By 2026, innovations in this sector are projected to shape the future. Reports indicate that polyethylene accounts for about 30% of the world's plastic production. This significant share highlights the urgent need for sustainable practices.

Recent studies show that more than 300 million tons of plastic are produced annually. A significant portion is polyethylene plastic, often criticized for its environmental impact. Innovations are crucial, yet many companies still struggle with responsible production methods. The call for alternatives and recycling solutions is louder than ever.

Advancements in biodegradable polyethylene are promising but require further evaluation. Sustainability is a journey, not a destination. Reputation is at stake. Businesses must balance between profit and ecological responsibility. The potential for positive change exists, but too many hurdles remain. As the industry moves forward, collaboration and transparency will be vital for meaningful progress.

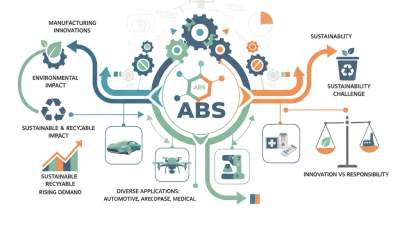

The polyethylene industry is poised for significant advancements in 2026. Innovations in production technologies are at the forefront, emphasizing sustainability. For instance, using catalyst developments can increase efficiency by 30% while reducing energy consumption. This shift addresses the critical need for eco-friendly solutions. Reports suggest that circular economies could potentially reduce plastic waste by over 50%.

One notable trend is the rise of bio-based feedstocks. Utilizing renewable resources can cut carbon footprints significantly. Companies are exploring alternatives such as plant-derived ethylene. These innovations not only help the environment but can also improve overall product quality. The focus on sustainable practices is not just a trend; it’s a necessity.

Polyethylene recycling is a growing concern. According to the Plastics Industry Association, approximately 30% of polyethylene products are recycled today. This number needs to rise significantly. Current practices often lead to waste, as many materials end up in landfills. Improving collection systems is crucial for enhancing recycling rates.

Innovative technologies are emerging to tackle these issues. Processes like chemical recycling can break down plastics into their basic components. This method increases the feasibility of recycling contaminated materials. A study from the American Chemical Society highlights that chemical recycling can potentially increase recycling rates by up to 50%. However, these technologies are still under development and require investment.

Many companies are striving for sustainability. However, a significant gap remains in the efficiency of recycling programs. Many consumers still have limited access to recycling facilities. Confusion about what can be recycled slows down progress. Collaboration among stakeholders is essential to create effective recycling solutions. A more informed public could lead to better recycling habits. Yet, there's still uncertainty about the long-term impact of these changes.

The growing concern over plastic waste has driven innovation in biodegradable polyethylene alternatives. Research indicates that traditional polyethylene can take hundreds of years to decompose, contributing to environmental crises. A 2023 report from the World Plastics Association states that 380 million tons of plastic are produced globally each year, with only 9% recycled. This stark statistic highlights the urgent need for alternatives.

Emerging biodegradable options are beginning to enter the market. Some bio-based polyethylene materials are designed to degrade more rapidly in the environment. They break down within a few years, significantly reducing long-term pollution. A recent study found that these alternatives can lower greenhouse gas emissions by up to 25% during production. However, challenges persist. Biodegradable plastics may not always break down as intended in certain environments, such as oceans or landfills. Quality control and appropriate disposal methods remain a concern.

Consumer awareness is rising, but many remain unaware of these alternatives. Educating the public is crucial. The transition to biodegradable solutions is not just about creating new materials. It involves a complete shift in how we perceive and manage plastic waste. As innovations progress, ongoing research and dialogue are necessary. We must analyze the ecological impacts. The path toward sustainable polyethylene practices needs continuous examination and adjustment.

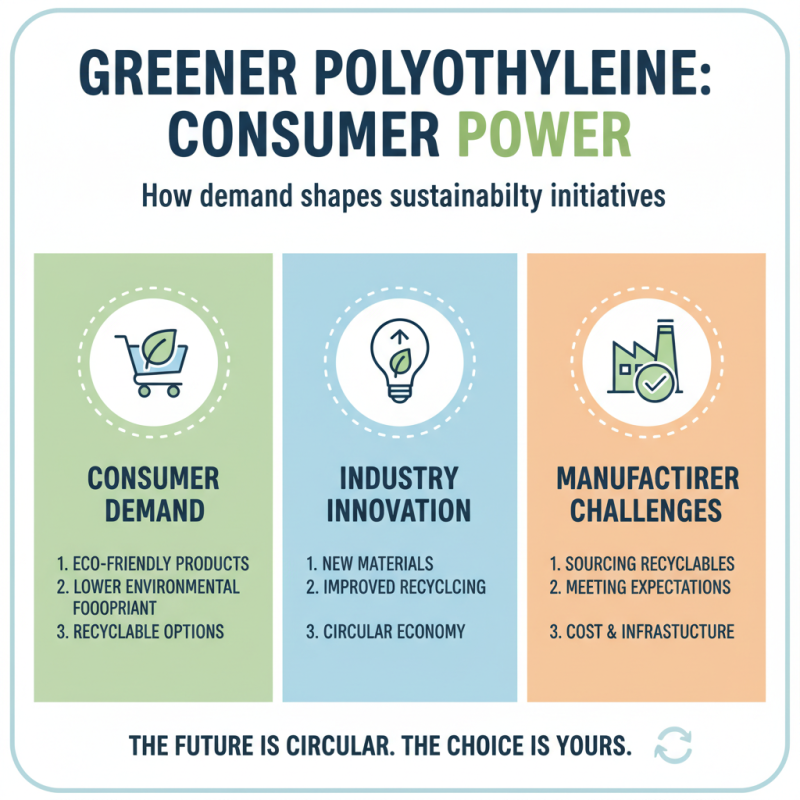

Consumer trends are increasingly shaping polyethylene sustainability initiatives. Today’s customers demand greener options. They prefer products with a lower environmental footprint. This shift is pushing manufacturers to innovate in eco-friendly ways. Many brands face challenges in sourcing recyclable materials. They seek solutions to meet consumer expectations.

Tips: Consider using biodegradable or easily recyclable plastics in your products. Simple changes can make a big impact.

Additionally, consumers are more aware of the lifecycle of plastics. They want transparency about production processes. This awareness leads to higher expectations for companies. Many businesses are still adapting. They must educate consumers on their efforts. This is crucial for building trust and loyalty.

Tips: Share sustainability achievements openly. Customers appreciate honesty and dedication. Keep them informed about your progress.

Ultimately, the push for polyethylene sustainability mirrors consumer values. It encourages companies to think critically about their practices. This is an opportunity for significant improvement. There is always room to grow and rethink strategies.

The regulatory landscape for polyethylene plastics is undergoing significant transformation. As sustainability concerns rise, industries must adapt. By 2026, research predicts that stricter regulations will shape the way polyethylene is produced and used. The Global Plastic Alliance indicates that 75% of companies are preparing for regulatory changes.

Governments are prioritizing the reduction of plastic waste. This means more focus on recycling and biodegradable alternatives. Recent data shows that countries implementing bans on single-use plastics have seen a 30% reduction in plastic waste. Industries have to rethink their strategies.

Tips: Innovate with eco-design principles. Materials should be easier to recycle. Engage with stakeholders to foster transparency.

Compliance with new regulations is not just a matter of legal obligation; it’s a business necessity. Companies still struggle in measuring their sustainability impact. Integrating sustainability metrics into business models is crucial for future relevance.