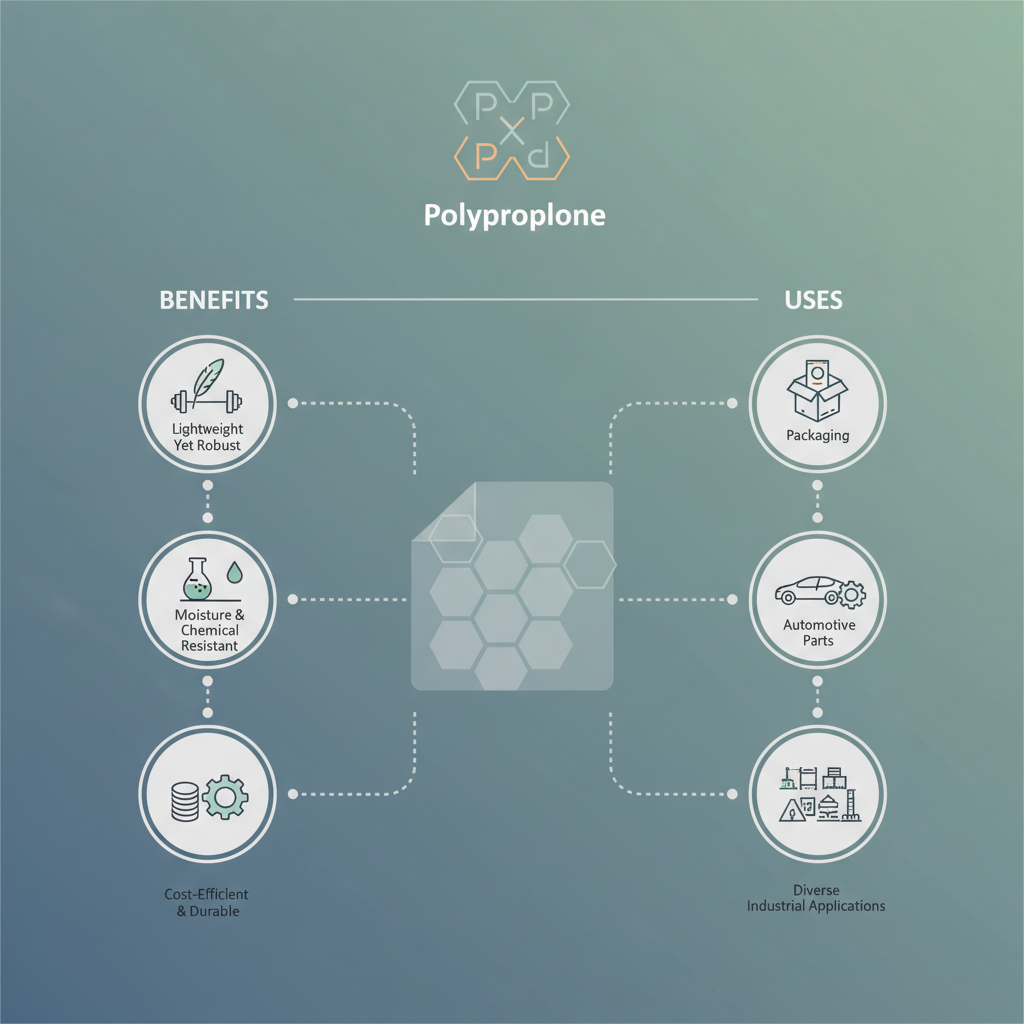

Polypropylene sheets have emerged as a preferred material for a variety of applications, demonstrating versatility and durability across different industries. According to renowned plastics expert Dr. Lisa Thompson, "The adaptability of polypropylene sheets not only meets various project specifications but also promises longevity and cost-efficiency in manufacturing processes." This highlights the significant advantages of incorporating polypropylene sheets into your next project.

From packaging to automotive parts, the uses of polypropylene sheets are vast and varied. They are lightweight yet robust, making them an ideal choice for applications requiring both strength and flexibility. Their resistance to moisture and chemicals further enhances their appeal, ensuring that they can withstand harsh environments without deteriorating. In this exploration of the benefits and uses of polypropylene sheets, we will delve into their unique properties that make them an essential material for modern projects, as well as the innovative ways industries are leveraging this remarkable product.

Polypropylene sheets are becoming increasingly popular across various industries due to their unique combination of benefits. One of the primary advantages is their lightweight yet durable nature, making them ideal for applications such as packaging, automotive parts, and even medical supplies. The chemical resistance of polypropylene means it won't degrade easily when exposed to solvents or harsh environments, which extends the life of products made from this versatile material.

When considering using polypropylene sheets for your next project, it's beneficial to understand their potential uses. They are perfect for creating containers, signage, and protective barriers due to their ease of fabrication and versatility in design. Additionally, their ability to be processed and recycled adds an environmentally friendly aspect, appealing to sustainability-focused projects.

**Tips:** Always check the working temperature range of polypropylene for your specific application to ensure optimal performance. Additionally, when cutting or machining the sheets, use sharp tools and appropriate techniques to achieve the best finish without damaging the material. Lastly, explore creative printing options on polypropylene sheets, as they can effectively display vibrant graphics and information, perfect for branding and advertising purposes.

| Application | Benefits | Characteristics |

|---|---|---|

| Packaging | Lightweight, Durable, Moisture-resistant | Flexible, Easy to fabricate |

| Automotive Parts | High strength-to-weight ratio, Cost-effective | Impact-resistant, Chemical resistance |

| Medical Applications | Biocompatible, Sterilizable | Transparent, Non-toxic |

| Construction | Weather-resistant, UV-stable | Lightweight, Rigid |

| Electronics | Electrical insulation, Lightweight | Thermal stability, Moisture-resistant |

Polypropylene sheets are renowned for their impressive durability and chemical resistance, making them a top choice for a variety of applications. This lightweight yet robust material is highly resistant to a range of chemicals, including acids, bases, and solvents. As a result, polypropylene sheets are ideal for industries such as packaging, automotive, and healthcare, where exposure to harsh substances is common. Their durability also ensures that they can withstand significant wear and tear, making them a long-lasting option for diverse projects.

Tips: When working with polypropylene sheets, consider using a heat gun to make precise cuts, as this will help to avoid any potential cracking at the edges. Additionally, always clean the surface thoroughly before applying any adhesives or paints; this will ensure better adhesion and longevity of the finished product.

The versatility of polypropylene does not end with its physical properties. It is easily customizable, allowing for various thicknesses, colors, and finishes to meet specific project requirements. This adaptability makes it suitable for applications ranging from signage and displays to storage containers and medical equipment. By choosing polypropylene sheets, you are investing in a material that combines functionality with resilience.

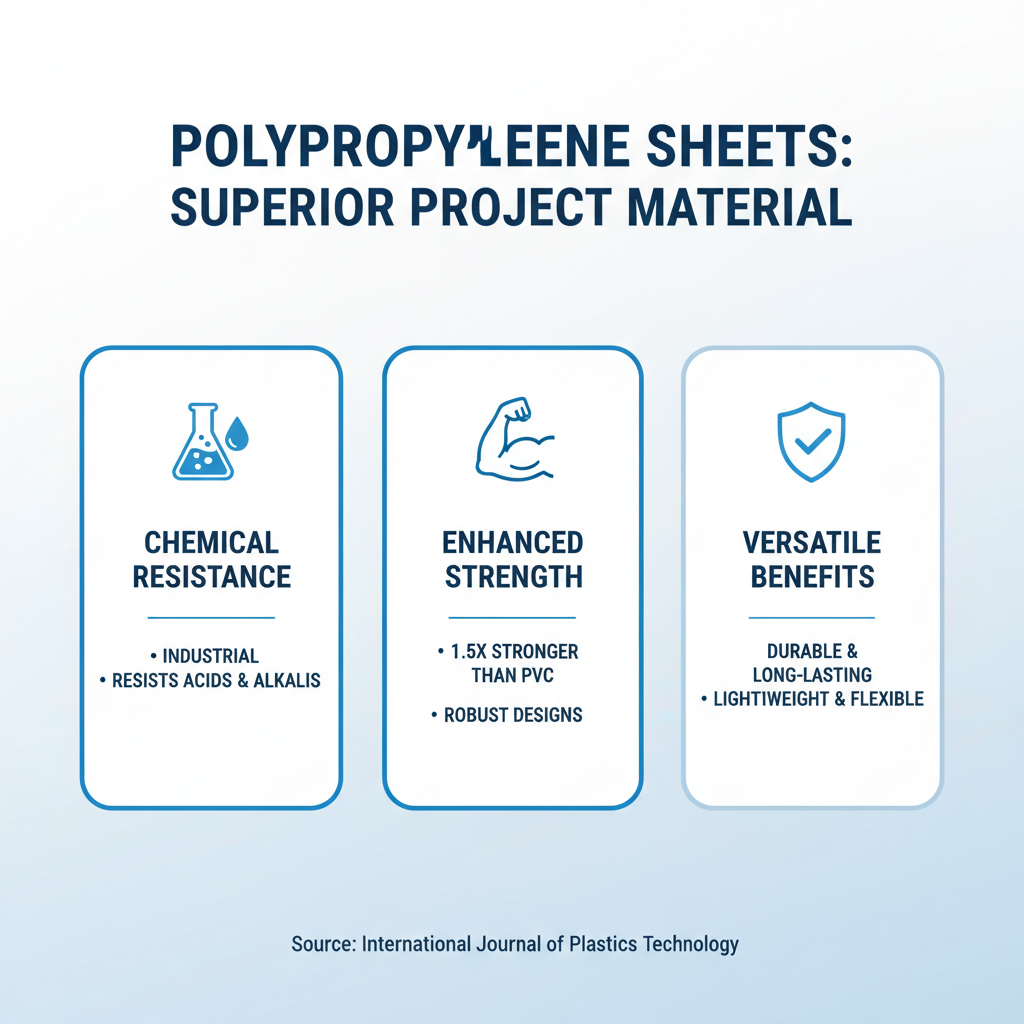

When selecting materials for projects, polypropylene sheets stand out due to their unique properties and benefits. Compared to traditional materials like PVC and polyethylene, polypropylene offers superior chemical resistance, making it ideal for industrial applications. According to a report by the International Journal of Plastics Technology, polypropylene has a tensile strength that is approximately 1.5 times greater than that of PVC, allowing for more robust designs and reducing the likelihood of material failure under stress.

Additionally, polypropylene is much lighter than both PVC and polyethylene, which can significantly reduce transportation and handling costs. A study by the Plastics Industry Association indicates that the lightweight nature of polypropylene translates to a 25% decrease in shipping expenses for manufacturers. Furthermore, polypropylene is fully recyclable, aligning with the increasing demand for sustainable materials. This environmentally friendly aspect, coupled with its durability and versatility, positions polypropylene as a superior option in numerous applications, ranging from packaging to automotive components, making it a wise choice for modern projects.

Polypropylene sheets have gained significant traction in various industries due to their versatile properties and cost-effectiveness. Key sectors utilizing these sheets include packaging, automotive, medical, and construction. According to a Grand View Research report, the global polypropylene market was valued at over USD 120 billion in 2022, with a projected compound annual growth rate (CAGR) of 5.3% from 2023 to 2030. This growth is driven largely by the demand for lightweight and durable materials in manufacturing processes.

In the packaging industry, polypropylene sheets are favored for their excellent moisture resistance and ability to be thermally sealed. They are widely used for making containers, lids, and films, which are critical for food and pharmaceutical packaging where hygiene and safety are paramount. The medical sector benefits similarly, as polypropylene's ability to be sterilized makes it ideal for surgical trays and various medical devices.

Tip: When selecting polypropylene sheets, consider their thickness and type, as these factors significantly affect performance based on industry requirements. Additionally, look for suppliers who offer customizable options to fit your specific project needs for enhanced functionality and efficiency.

Polypropylene sheets are not only versatile in their applications but also present significant environmental advantages, particularly in terms of recycling potential. Made from a thermoplastic polymer, polypropylene is lightweight yet durable, making it an ideal choice for various projects. One of its standout features is the ability to be recycled efficiently. Many polypropylene manufacturers and recycling facilities actively promote the collection and repurposing of these sheets, contributing to a circular economy. This means that when a project utilizing polypropylene sheets reaches its end of life, the material can be processed and transformed into new products, reducing the overall waste sent to landfills.

Moreover, the environmental impact of polypropylene sheets extends beyond their recyclability. The production of polypropylene often requires fewer resources compared to other plastics, resulting in a lower carbon footprint. Additionally, the material is resistant to moisture, chemicals, and UV radiation, which prolongs its lifespan and further minimizes environmental degradation. As consumers become increasingly aware of their ecological footprints, choosing polypropylene sheets not only supports sustainable practices but also ensures that projects can adapt to modern environmental standards.

This chart illustrates the benefits and environmental impact of polypropylene sheets, focusing on their advantages and recycling potential. The data highlights the various attributes contributing to their widespread use in different industries.