In the ever-evolving landscape of manufacturing, efficiency and innovation are paramount, particularly in the production of plastic products. As more industries recognize the advantages of advanced manufacturing techniques, the plastic extrusion machine has emerged as a crucial asset. Renowned industry expert Dr. Emily Carter, a leading researcher in polymer processing, emphasizes the significance of this technology, stating, “The plastic extrusion machine is not just a tool; it is a gateway to greater productivity and customization in manufacturing processes.”

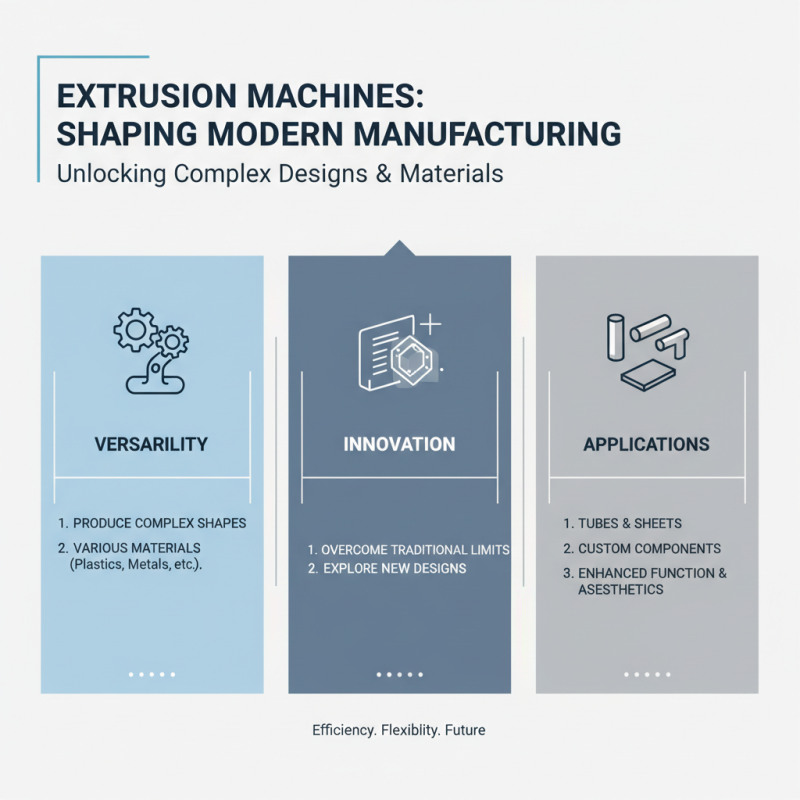

The versatility offered by plastic extrusion machines allows manufacturers to create a wide array of products, ranging from packaging materials to complex components used in automotive and construction applications. By continuously extruding and shaping plastic materials, these machines enhance production speeds and reduce waste, marking a significant leap in manufacturing efficiency. With increased demand for sustainable practices, the advantages of utilizing a plastic extrusion machine become even more relevant, paving the way for innovative solutions that align with environmental goals.

As we delve into the top ten benefits of using a plastic extrusion machine in manufacturing, it becomes clear that these machines not only revolutionize production methods but also contribute to the overall success and sustainability of the operations. Understanding these benefits is essential for any manufacturer looking to thrive in a competitive market.

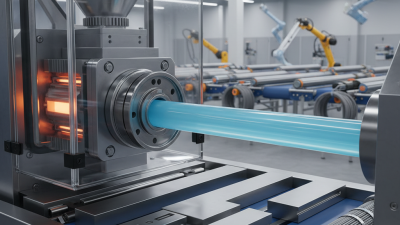

Plastic extrusion machines have revolutionized the manufacturing sector by significantly enhancing efficiency. One of the key advantages is the streamlined production process. These machines allow for continuous shaping of plastic materials, reducing the time and labor needed for production. By minimizing manual handling and accelerating the output speed, manufacturers can meet high demand while maintaining consistent quality. This efficiency not only accelerates production times but also reduces downtime and labor costs.

When integrating plastic extrusion machines, it’s essential to consider some practical tips to maximize efficiency. First, ensure regular maintenance of the machines to prevent breakdowns that can halt production. Establish a routine for cleaning and inspecting critical components, which will help maintain optimal performance. Secondly, invest in employee training to ensure that staff are skilled in operating and troubleshooting the machines. This initiative can drastically reduce the time required for problem resolution and further enhance production flow.

Moreover, optimizing the use of raw materials can significantly impact effectiveness. Implementing a system for recycling scrap plastic during the extrusion process can lead to more sustainable practices while also lowering production costs. By focusing on these strategies, manufacturers can harness the full potential of plastic extrusion machines, resulting in increased output and reduced wastage, leading to greater overall efficiency in their operations.

Using extrusion technology in manufacturing offers significant cost reductions that can greatly enhance operational efficiency. According to a report by the Plastics Industry Association, companies utilizing plastic extrusion can save up to 30% in production costs compared to traditional manufacturing methods. This reduction is largely due to the streamlined production process that extrusion machines facilitate, which allows manufacturers to produce large volumes of products with minimal waste. The ability to create complex shapes without additional assembly also contributes to lower labor costs, making extrusion an attractive option for many manufacturers.

Tips: When investing in extrusion technology, consider the total cost of ownership, which includes initial setup costs, operational expenses, and maintenance. It's essential to invest in high-quality machinery to maximize efficiency over time. Additionally, regularly reviewing the production process can help identify areas for further cost savings and improvements.

Furthermore, the energy efficiency of modern extrusion machines is a significant factor in cost reduction. A study published by the American Council for an Energy-Efficient Economy indicates that state-of-the-art extrusion equipment can reduce energy consumption by as much as 50%. By optimizing energy use, manufacturers not only lower their bills but also decrease their carbon footprint, aligning with sustainable manufacturing goals. Properly training staff on energy-efficient practices can further enhance these savings.

Sustainable plastic extrusion practices offer numerous environmental benefits that can significantly reduce the ecological footprint of manufacturing processes. By focusing on recycling and utilizing biodegradable materials, companies can minimize waste and pollution. The plastic extrusion process can be optimized to use less energy and generate lower emissions, promoting a cleaner production environment. Implementing efficient recycling systems within the extrusion operation not only conserves resources but also supports the circular economy by reintroducing materials back into the production cycle.

Tips for manufacturers include investing in energy-efficient machinery and exploring alternative materials that are more sustainable. Regular maintenance and upgrades of existing equipment can enhance efficiency and reduce energy consumption. Additionally, collaborating with suppliers who prioritize sustainability can lead to more eco-friendly raw material options, further decreasing the overall environmental impact of plastic extrusion.

Another important aspect of sustainable practices in plastic extrusion is the incorporation of eco-design principles. By considering the lifecycle of products from conception to disposal, manufacturers can create designs that require less material and are easier to recycle at the end of their lifespan. Training employees on sustainability practices also fosters a culture of responsibility and innovation, ensuring that environmental considerations are at the forefront of production processes.

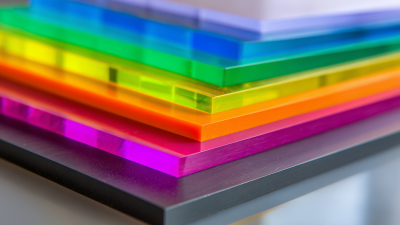

The versatility of extrusion machines plays a significant role in modern manufacturing, particularly in the ability to produce complex shapes efficiently. These machines can manipulate various materials, including plastics and metals, to create intricate profiles that meet specific design requirements. This capability allows manufacturers to explore innovative designs without being limited by traditional machining methods. From tubes and sheets to custom components, extrusion molds can be tailored to achieve unique forms that enhance product functionality and aesthetics.

When utilizing a plastic extrusion machine, it’s crucial to optimize the design process to fully leverage its capabilities. One tip is to ensure that your designs accommodate the flow characteristics of the material being used. This consideration can prevent issues such as warping or inconsistent wall thickness during production. Additionally, collaborating closely with engineers and material experts during the design stage can lead to more effective use of the extrusion process. They can offer insights into the best practices for shaping the materials, which will ultimately streamline production and reduce waste.

Moreover, maintaining a flexible design approach will yield a higher adaptability in production. As market demands fluctuate, the ability to produce a range of shapes from a single machine can make a considerable difference. Emphasizing modular designs or features that allow for easy adjustments can save time and resources. Overall, the versatility of extrusion machines not only opens doors for innovating complex shapes but also ensures that manufacturers can respond nimbly to market trends.

Quality control in manufacturing is a critical aspect that significantly influences product performance and customer satisfaction. With the advent of advanced extrusion techniques, plastic extrusion machines have revolutionized the quality control processes in the industry. According to a report from the American Society of Plastics Engineers, manufacturers utilizing sophisticated extrusion technology experience a 30% reduction in production defects, allowing for more consistent product quality and minimized wastage.

One of the most significant improvements in quality control is the capacity for real-time monitoring and adjustments during the extrusion process. Advanced machines equipped with sensors and data analytics capabilities can immediately identify discrepancies in material composition or processing temperatures. A study published in the Journal of Polymer Science indicates that real-time quality assessments can lead to a more than 20% increase in the overall efficiency of production lines, further enhancing the reliability of extruded products. This proactive approach not only ensures compliance with quality standards but also enhances the brand reputation in a competitive market.

Moreover, the integration of automation in plastic extrusion machinery contributes to better repeatability and accuracy. With precise control over the extrusion parameters, manufacturers can achieve tighter tolerances, which is essential for applications requiring high-performance materials. The Plastics Industry Association reports that industries such as automotive and aerospace have seen up to a 15% improvement in material performance due to enhanced extrusion quality control measures. Continuous innovations in extrusion technology thus not only drive productivity but also ensure that manufacturers consistently deliver high-quality products that meet or exceed market expectations.