In a rapidly evolving industrial landscape, the choice of materials can significantly impact the durability, efficiency, and sustainability of projects. Among various materials, HDPE sheets have emerged as a preferred option due to their remarkable versatility and exceptional properties. According to a recent market study by Research and Markets, the global HDPE sheets market is projected to reach approximately $6 billion by 2025, highlighting a growing recognition of their beneficial applications across multiple sectors, particularly in construction, packaging, and manufacturing.

HDPE sheets, known for their high density and excellent chemical resistance, offer a range of advantages that cater to diverse project requirements. Their lightweight nature, coupled with impressive strength, makes them ideal for applications that demand both reliability and ease of handling. Furthermore, reports from the Plastics Industry Association indicate that the use of HDPE sheets contributes to reducing environmental impact, as they are fully recyclable and contribute to sustainable practices in various industries. As we delve into the top benefits of incorporating HDPE sheets into your projects, it becomes evident why they are increasingly favored by professionals seeking both performance and environmental responsibility.

HDPE (High-Density Polyethylene) sheets have become increasingly popular in construction and design projects due to their remarkable advantages. One of the primary benefits is their exceptional durability. According to a 2021 industry report by Grand View Research, the global HDPE market is projected to reach USD 76 billion by 2025, highlighting its widespread use across various applications, including construction. HDPE sheets are resistant to impact, moisture, and chemicals, making them ideal for both indoor and outdoor environments. This robustness translates to reduced maintenance costs and longer service life compared to traditional materials.

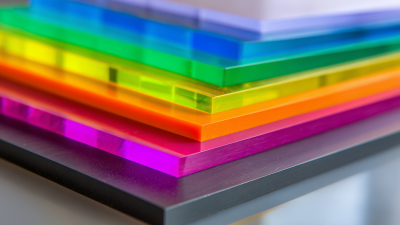

Incorporating HDPE sheets into design projects also enhances aesthetic versatility. Available in multiple colors and finishes, these sheets can be easily customized, allowing architects and designers to create unique looks while meeting functional demands. A study by Markets and Markets indicates that the design and construction sector is increasingly favoring sustainable materials, and HDPE fits this criterion well, being 100% recyclable.

Tips: When selecting HDPE sheets for your project, consider sourcing them from reputable suppliers who provide detailed specifications and certifications. Additionally, always evaluate the specific environmental conditions your installation will face, as this can impact material performance over time.

High-Density Polyethylene (HDPE) sheets are quickly becoming the material of choice for various construction and industrial applications, thanks to their impressive durability and longevity. According to a report by the Plastics Industry Association, HDPE has a lifespan of over 50 years when used in the right conditions, making it a sustainable option for long-term projects. The material’s resistance to impacts, chemicals, and moisture ensures that it maintains its integrity even in harsh environments, reducing the need for frequent replacements and repairs.

Furthermore, in a comprehensive study by the American Society for Testing and Materials (ASTM), HDPE has demonstrated remarkable performance in stress-crack resistance and tensile strength. This means that projects utilizing HDPE sheets are less likely to experience failure due to physical stressors, translating to lower maintenance costs over time. By investing in HDPE, businesses not only enhance the durability of their projects but also achieve significant savings, as reduced frequency of material replacement and repair leads to lower overall lifecycle costs.

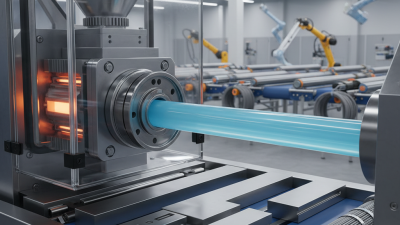

High-Density Polyethylene (HDPE) sheets have emerged as a crucial material in diverse industries owing to their remarkable versatility and durability. According to a report by Grand View Research, the HDPE market is expected to reach USD 66.8 billion by 2025, driven primarily by its extensive applications. In construction, HDPE sheets are used for waterproofing and as vapor barriers, contributing to enhanced energy efficiency in buildings. Their resistance to chemicals and high impact strength makes them ideal for agricultural applications, such as greenhouse construction and livestock flooring, where longevity and safety are paramount.

Furthermore, the automotive industry leverages HDPE sheets for lightweight components that contribute to fuel efficiency while maintaining structural integrity. A study published in the Journal of Cleaner Production highlights that replacing traditional materials with HDPE in automotive applications can reduce vehicle weight by up to 10%, improving overall performance and lowering emissions. Similarly, in the healthcare sector, HDPE sheets provide hygienic surfaces that are easy to clean and resistant to bacteria, making them a preferred choice for medical facilities.

The versatility of HDPE sheets, evident across these varied industries, underscores their essential role in modern manufacturing and construction processes.

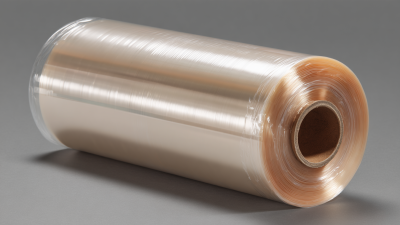

The ease of maintenance of HDPE sheets is one of the standout benefits that make them an attractive option for various projects.

HDPE, or high-density polyethylene, is renowned for its durability and resilience, which means that structures made with this material can look new for much longer compared to those made with traditional materials.

As it is non-porous, HDPE is resistant to stains, chemicals, and moisture, making cleaning straightforward and requiring minimal effort.

This inherent quality significantly reduces the time and cost associated with ongoing maintenance.

Recent market insights reveal that the global HDPE market is expected to see substantial growth, with projections estimating it will increase from

USD 25.24 billion in 2025 to USD 37.96 billion by 2033.

This booming demand underscores the material's pivotal role in modern infrastructure development, particularly in piping systems designed for water distribution and other critical applications.

The longevity and low-maintenance attributes of HDPE not only enhance project efficiency but also contribute to sustainable practices by minimizing the need for frequent replacements and repairs, aligning with global initiatives for smarter, more sustainable infrastructure.

When considering materials for various projects, HDPE (High-Density Polyethylene) sheets stand out not only for their durability and versatility but also for their cost-effectiveness. One of the most compelling reasons to choose HDPE sheets is their ability to deliver long-term savings. Unlike traditional materials, HDPE sheets have a longer lifespan and can withstand harsh environmental conditions without deteriorating. This durability translates into fewer replacements and repairs over time, significantly reducing overall project costs.

Additionally, HDPE sheets are lightweight yet strong, making them easy to handle and install. This can lead to lower labor costs during the installation process, further contributing to financial savings. The material's resistance to chemicals and moisture means that maintenance costs remain minimal, which is particularly advantageous in industrial settings. By investing in HDPE sheets, project managers and contractors benefit not only from an initial lower expenditure but also from substantial savings throughout the life of the project.