In the fast-paced world of packaging, the use of plastic roll has gained significant attention. According to a recent market report by Smithers Pira, the global flexible plastic packaging market is projected to reach $300 billion by 2025. This growth highlights the importance of efficient and versatile packaging solutions. Plastic rolls cater to diverse needs, from food packaging to industrial uses, proving their adaptability.

However, the benefits of plastic rolls extend beyond just convenience. They are lightweight, cost-effective, and available in various thicknesses and sizes. In fact, a study by the Plastic Packaging Industry Association reveals that over 75% of businesses prefer plastic rolls for their packaging solutions. Yet, this reliance on plastic raises questions about sustainability and environmental impact. While plastic rolls offer ease and efficiency, companies must also consider the long-term implications of their packaging choices.

Ultimately, exploring the top benefits of using plastic rolls can help businesses make informed decisions. Balancing performance with environmental responsibility remains a crucial challenge. Understanding the advantages and reflecting on their impact is essential for future packaging strategies.

Plastic rolls are versatile materials widely used in various packaging applications. They offer protective features, making them ideal for industries like food, e-commerce, and manufacturing. According to a recent report by Smithers, the global plastic packaging market is projected to reach over $500 billion by 2027. This growth highlights the demand for efficient packaging solutions.

Common uses of plastic rolls include shrink wrap, stretch film, and pallet wrap. These products help secure goods during transport and storage. They can prevent moisture, dust, and damage. Studies show that around 70% of businesses prefer plastic roll packaging for its cost-effectiveness and durability. However, reliance on plastic brings environmental concerns. A large percentage of plastic waste ends up in landfills, which raises questions about sustainable practices in packaging.

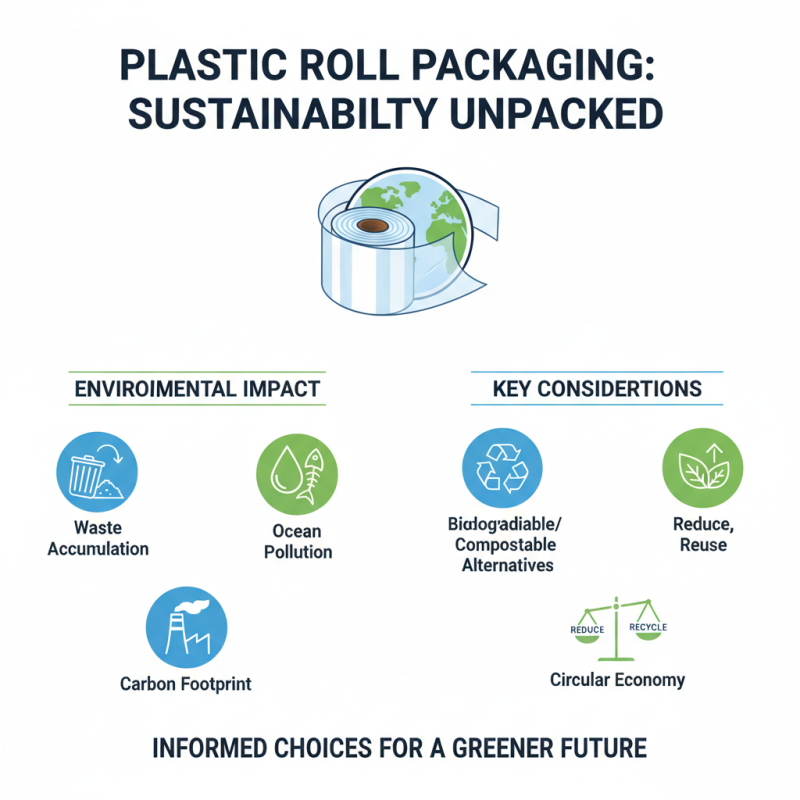

Balancing efficiency and environmental impact is a challenge. Companies must consider biodegradable options or recycling programs. The future of plastic roll usage hinges on innovation in sustainable materials. Addressing these issues could redefine packaging practices, but progress is slow. The industry faces a crucial moment in deciding its trajectory.

When considering packaging solutions, plastic rolls offer significant advantages. They are lightweight and flexible, making them easy to handle. This flexibility allows for unique configurations, suitable for various product shapes. Additionally, plastic rolls can provide enhanced protection from moisture and dust. This is crucial for preserving product integrity.

Tips: Always test different types of plastic for durability. Consider the thickness based on your product's needs. A thicker roll may add weight, but it can offer better protection.

Using plastic rolls also means reduced waste. They can be cut to specific lengths, minimizing excess material. This aspect is essential for cost-effective packaging scenarios. However, it's important to remember that excessive reliance on plastic can be problematic.

Sustainability should be part of the conversation. While plastic rolls are convenient, you might rethink their environmental impact. Explore recyclable options. Balancing usability and eco-friendliness is key for a better future.

Plastic rolls have increasingly gained attention in the packaging industry due to their cost-effectiveness. A recent industry report by Smithers revealed that plastic films and rolls can reduce packaging costs by up to 30% compared to traditional materials. These savings stem from the lower raw material costs and reduced shipping expenses. Additionally, plastic rolls are often lighter than alternatives, leading to lower transportation costs. This is a significant consideration for businesses aiming to optimize their bottom line.

Moreover, the versatility of plastic rolls plays a crucial role in their economic benefits. They can be tailored to meet various packaging needs, from food to industrial products. According to a study by MarketsandMarkets, the global demand for flexible packaging is expected to reach $320 billion by 2025. This rise reflects the efficiency and adaptability of plastic rolls. However, there are challenges. While they offer numerous benefits, there are still concerns about environmental impact. The industry must address recycling and sustainability practices as demand grows. Balancing cost advantages with eco-friendly solutions remains a vital consideration for future development.

When it comes to packaging, plastic rolls often face scrutiny. Their environmental impact raises questions about recycling and sustainability. However, understanding these aspects is crucial for making informed decisions.

Recycling plastic rolls isn't as straightforward as it seems. Not all types of plastic are recyclable. Many people remain unaware of this. Sorting and cleaning are essential steps in the recycling process. Without proper handling, a significant amount ends up in landfills. This is a critical issue that needs attention. Educating consumers about proper disposal methods is necessary.

Sustainability is a key concern as well. Innovations in materials aim to produce more eco-friendly options. Some companies focus on biodegradable plastics. These alternatives could reduce the environmental footprint. However, the cost of such materials often deters businesses. It’s a delicate balance between cost and ecological responsibility. The pressure to choose economically viable solutions often overshadows longer-term benefits. Awareness and commitment to sustainability must grow within industries to create real change.

Plastic rolls are gaining traction across various industries. Their versatility makes them a preferred choice for packaging. According to a report by Smithers Pira, the global market for flexible plastic packaging is expected to reach 300 billion USD by 2025. This data highlights the increasing reliance on plastic rolls for efficient packaging solutions.

In the food sector, plastic rolls enhance product freshness. They create airtight seals, improving shelf life significantly. For example, vacuum-sealed packaging can extend shelf life by 50% or more. This not only reduces food waste but also enhances consumer satisfaction. In the medical industry, plastic rolls ensure sterile packaging for medical devices. As the demand for safety rises, this becomes critically important.

Despite their benefits, not all plastic rolls are created equal. Some may not provide adequate barrier properties. It's crucial to evaluate the specific needs of each application. Understanding the nuances can prevent packaging failures. Exploring eco-friendly options can also pose challenges, as they may not always meet durability requirements. Thus, while plastic rolls offer versatility, careful selection is essential for optimal performance.

| Benefit | Description | Industry Applications |

|---|---|---|

| Cost-effective | Plastic rolls are generally less expensive than traditional packaging materials. | Manufacturing, Food & Beverage |

| Lightweight | Easy to handle and transport, reducing shipping costs. | E-commerce, Retail |

| Durability | Resistant to moisture, chemicals, and physical damage. | Pharmaceuticals, Agriculture |

| Versatility | Can be used for various types of products and applications. | Automotive, Electronics |

| Customizable | Available in various sizes, colors, and thicknesses. | Consumer Goods, Packaging |

| Sustainability | Recyclable options are available, promoting eco-friendly practices. | Retail, Food Processing |

| Space-saving | Can be rolled up for efficient storage. | Warehousing, Logistics |

| Easy to Use | Convenient for manual or automated packaging processes. | Manufacturing, Distribution |

| High-Quality Sealing | Provides superior protection against contamination. | Food Storage, Chemical Packaging |