Vacuum forming plastic is an innovative manufacturing process that has gained significant traction across various industries due to its numerous advantages. As a method of shaping plastic sheets into specific forms by applying heat and vacuum pressure, vacuum forming plastic offers versatility that caters to a wide range of project needs. Whether it’s for prototyping, packaging, or creating custom parts, the benefits of this technique are invaluable for engineers and designers alike.

One of the standout features of vacuum forming plastic is its cost-effectiveness, especially for low to medium production runs. This makes it an attractive option for businesses looking to minimize expenses while still achieving high-quality results. Additionally, the ability to create intricate shapes and designs with relative ease means that vacuum forming plastic can be utilized in various applications, from automotive components to consumer products. The process not only yields durable results but also allows for quick turnaround times, facilitating faster project development and market entry.

In an era where customization and efficiency are paramount, understanding the key benefits of vacuum forming plastic can empower professionals to make informed decisions for their projects. As we delve into the top ten advantages of this remarkable process, we will explore how it can enhance both the functionality and aesthetic of products, ultimately driving innovation and success in various fields.

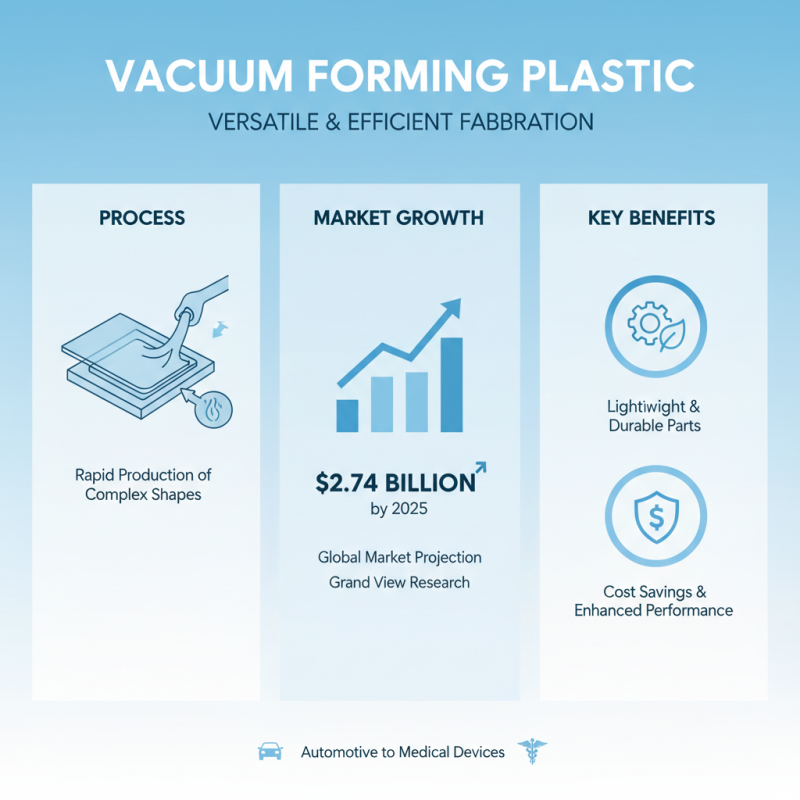

Vacuum forming plastic has gained significant traction in the realm of custom plastic fabrication, largely due to its versatility and efficiency. This process allows for the rapid production of complex shapes with high precision, making it an ideal choice for industries ranging from automotive to medical devices. According to a recent report by Grand View Research, the global vacuum forming market is projected to reach $2.74 billion by 2025, highlighting its growing relevance in various applications. The ability to create lightweight yet durable parts contributes not only to cost savings but also to enhanced performance characteristics, making vacuum forming a preferred method for many manufacturers.

One of the standout advantages of vacuum forming is its ability to produce prototypes quickly and economically. This is particularly valuable in product development cycles where time-to-market is crucial. By utilizing this method, companies can significantly reduce lead times compared to conventional production processes. Additionally, vacuum forming supports a wide array of materials, allowing designers the flexibility to choose the best fit for their specific needs, which can lead to better functionality and user experience.

Tips: When planning your project, consider using detailed CAD drawings to optimize the vacuum forming process. Accurate designs can minimize errors and reduce material waste. Also, keep in mind that maintaining a consistent temperature during the heating phase is essential for achieving uniform thickness and optimal forming results. Lastly, collaborating closely with your fabricator can facilitate smoother production runs and enhance the final product quality.

Vacuum forming is a popular manufacturing process that offers significant cost advantages for both small and large projects. For smaller projects, the low material waste associated with vacuum forming allows designers and engineers to experiment with prototypes at a fraction of the cost compared to traditional methods. The quick turnaround time in producing molds means that small businesses and startups can bring their ideas to life efficiently and affordably, enabling rapid iteration and development without the burden of heavy costs.

For larger projects, vacuum forming maintains its cost-effectiveness by allowing for the mass production of plastic parts on a wide scale. The ability to create large sheets of plastic that can be formed into various shapes reduces the overall production costs significantly. Additionally, the process requires less tooling than many other manufacturing methods, further decreasing both initial investment and production time. This makes vacuum forming an appealing choice for industries ranging from automotive to consumer goods, where creating high-quality parts in a cost-effective manner is crucial for competitive advantage.

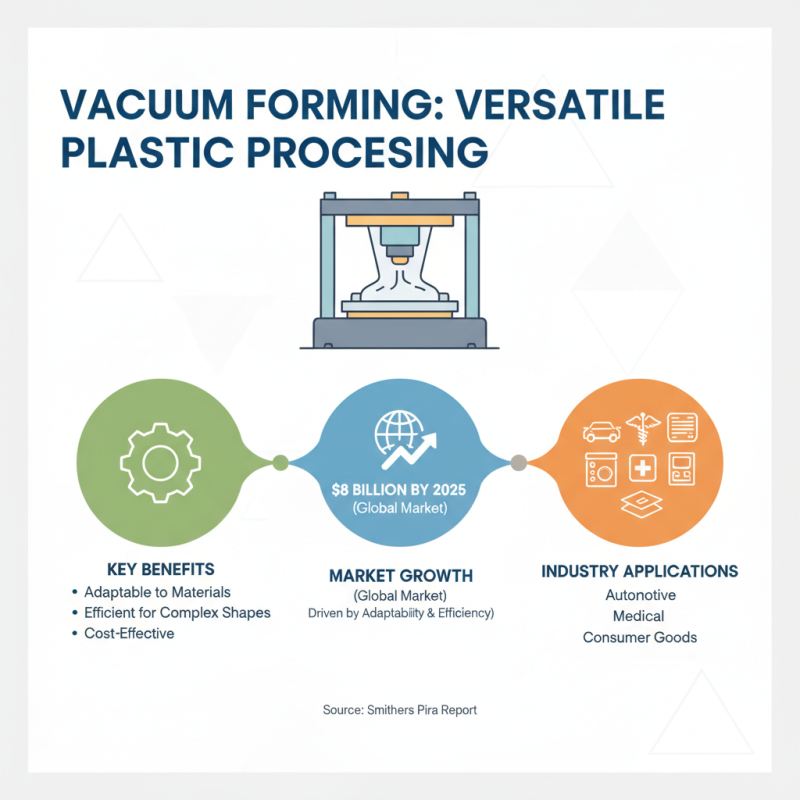

Vacuum forming is a highly versatile plastic processing technique, utilized across various industries including automotive, packaging, medical, and consumer goods. According to a report by Smithers Pira, the global vacuum forming market is expected to grow significantly, reaching approximately $8 billion by 2025. This rapid growth is driven by the method's adaptability to different materials and the ability to create complex shapes efficiently. The flexibility of vacuum forming allows manufacturers to produce everything from simple trays to intricate components, catering to the precise needs of each sector.

In the automotive industry, vacuum forming is extensively used for producing lightweight parts that contribute to fuel efficiency and performance. Research by Allied Market Research indicates that lightweight materials are a priority for auto manufacturers, with an increasing demand for effective reduction in vehicle weight. Vacuum forming supports this trend by enabling the production of durable yet lightweight components, thereby enhancing sustainability. Similarly, in the medical field, vacuum-formed plastic is used to create hygienic and customizable packaging solutions that meet stringent safety standards. The process not only ensures precision but also facilitates quick turnaround times, critical in a fast-paced healthcare environment. Overall, vacuum forming serves as a key technology that aligns with the evolving demands of multiple industries, delivering both quality and efficiency.

The vacuum forming process is renowned for its speed and efficiency, making it a favored choice in various manufacturing sectors. One of the key advantages of this method lies in its ability to produce high-quality plastic components in a fraction of the time compared to traditional molding processes. According to a report from the Institute of Packaging Professionals (IoPP), vacuum forming can reduce production times by up to 60%, enabling manufacturers to meet tight deadlines and respond quickly to market demands. This accelerated workflow is particularly beneficial for the production of prototypes and small batches, where quick turnaround is essential.

Additionally, the simplicity of the vacuum forming process contributes to its overall efficiency. The setup requires fewer tooling changes, and the process can be easily adjusted for different designs, minimizing downtime. A study by the Plastics Industry Association reveals that companies adopting vacuum forming have reported up to a 30% reduction in costs associated with labor and materials. This cost-effectiveness, combined with reduced production times, positions vacuum forming as a highly efficient manufacturing solution, particularly in industries such as packaging, automotive, and consumer goods. The ability to produce complex shapes with consistent quality further enhances its attractiveness to project managers aiming for both speed and precision in their manufacturing processes.

| Benefit | Description | Impact |

|---|---|---|

| Speed of Production | Rapid production capabilities reduce lead times. | Increased efficiency for project timelines. |

| Cost-Effectiveness | Lower material waste and fast turnaround times lead to reduced costs. | Enhances overall project budgets. |

| Design Flexibility | Allows for intricate designs and customizations. | Greater creativity in product development. |

| Material Variety | Supports various plastic materials, enhancing design options. | Broader application across industries. |

| Scalability | Easily adjustable for small or large production runs. | Flexibility for businesses of all sizes. |

| Durability | Produces sturdy and long-lasting products. | Increases product lifespan. |

| Quick Prototyping | Allows rapid creation of prototypes for testing. | Faster feedback and iteration process. |

| Reduced Labor Costs | Automated processes result in lower labor requirements. | Cost savings on workforce expenses. |

| Eco-Friendly Options | Utilization of recyclable materials available. | Promotes sustainability in manufacturing. |

| Safety | Production processes are often safer due to automation. | Minimized risk in the production environment. |

Vacuum forming plastic has emerged as a game-changer in the world of design flexibility and prototyping. Its ability to create complex shapes and detailed designs makes it an invaluable tool for manufacturers and designers across various industries. A recent industry report indicated that over 75% of designers noted improved workflow efficiency through vacuum forming, particularly in the rapid prototyping phase. This efficiency stems from the process's capability to quickly produce high-quality prototypes, allowing teams to validate designs faster and reduce time-to-market.

Tips: When utilizing vacuum forming for prototypes, always consider the thickness of the plastic sheet used. Thicker options may provide better durability but could limit the detail in your design. Test different materials to find the best balance between strength and design intricacy.

Furthermore, vacuum forming allows for the incorporation of intricate details and textures that would be difficult to achieve with traditional molding methods. By leveraging this technique, designers can experiment with various textures and finishes, enhancing the aesthetic appeal of their products. According to the Plastic Industry Association, the prototyping phase can be reduced by as much as 40% when vacuum forming is implemented effectively. This reduction not only accelerates the development process but also opens up new avenues for creative design exploration.

Tips: Always create a thorough design plan before starting the vacuum forming process. Consider using CAD software to visualize your prototype, ensuring all details are accounted for prior to production.