When planning your next project, consider polyethylene plastic. This versatile material offers numerous benefits for various applications. Durability is one of its standout features. Polyethylene plastic is resistant to impacts, moisture, and chemicals. This makes it ideal for outdoor usage and industrial settings. Think of playground equipment, packaging, or piping systems.

Moreover, polyethylene plastic is lightweight and easy to manipulate. Its flexibility allows for creative designs and efficient installation. However, not all projects may benefit equally from this material. You might need to weigh its cost against other options. Some may question its environmental impact, as plastic waste remains a concern. Exploring recycling possibilities is crucial in making a responsible choice.

Ultimately, polyethylene plastic can enhance many projects if used thoughtfully. It opens doors to innovation. Choosing the right material requires careful consideration of needs and potential consequences. Being mindful of both advantages and disadvantages will guide your decision-making.

Polyethylene plastic, often chosen for its versatile properties, offers a range of benefits. It is lightweight, making it easy to handle and transport. This characteristic enhances efficiency in manufacturing processes. According to recent industry data, polyethylene accounts for over 34% of the global plastic market. Its popularity reflects its reliability and adaptability across various applications.

Another notable property is resistance to moisture. Polyethylene is waterproof, which prevents degradation in wet environments. This feature is crucial for packaging and agricultural films. Research shows that the durability of polyethylene can lead to an extended lifespan of products. Yet, concerns remain about environmental impact. The recycling rate for polyethylene hovers around just 9%. This highlights the ongoing challenges in sustainability efforts.

Despite its advantages, there are limitations. Polyethylene lacks strength at high temperatures. Also, it may not meet the requirements for every application. To maximize its use, careful consideration is needed in design and processing. Each project demands a tailored approach to leverage polyethylene's benefits effectively.

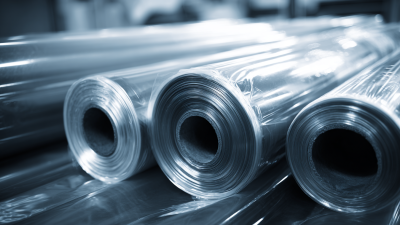

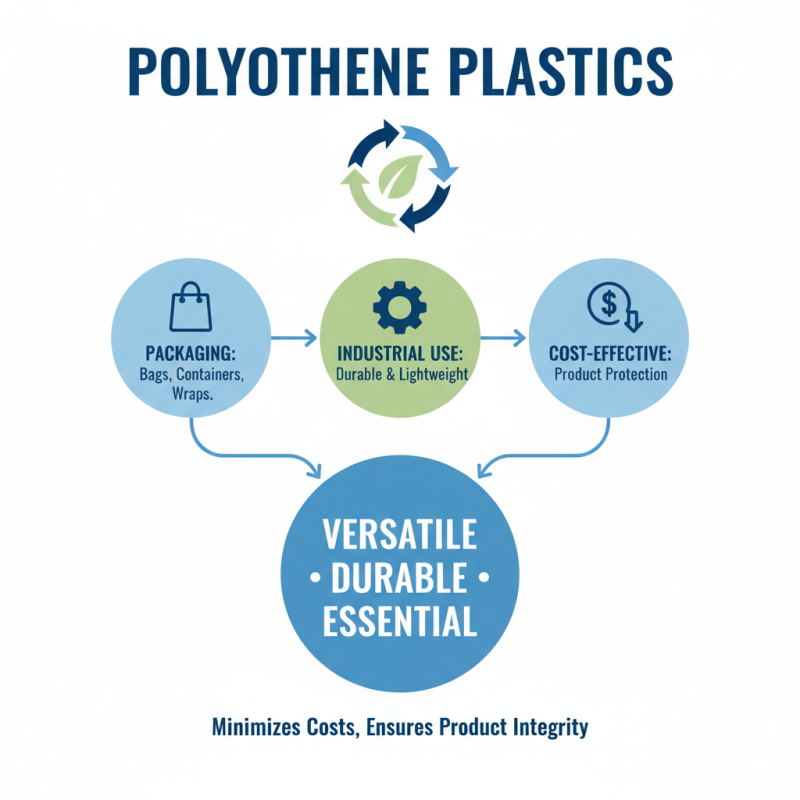

Polyethylene plastic is widely used across various industries for its unique properties. Its lightweight yet durable nature makes it ideal for packaging. You'll find it in grocery bags, food containers, and even protective film wraps. This versatility allows businesses to minimize costs while ensuring their products remain intact.

In the construction sector, polyethylene is often used for vapor barriers and insulation. Its resistance to moisture helps maintain building integrity. However, there are environmental concerns regarding its disposal. Many regions struggle with plastic waste management. This aspect prompts industries to rethink their sourcing and recycling strategies.

Healthcare also benefits from polyethylene’s properties. It's used for sterile medical packaging and disposable items. The flexibility in design meets strict hygiene standards. Yet, the reliance on single-use plastics raises sustainability questions. Balancing convenience with environmental responsibility is an ongoing challenge. These reflections on its applications highlight both its practical advantages and the need for responsible usage.

When selecting materials for your next project, polyethylene plastic is worth considering. It stands out among other plastics like polypropylene or PVC. Polyethylene offers great flexibility, making it ideal for various applications. Its lightweight nature reduces shipping costs and makes handling easier.

One key feature of polyethylene is its resistance to chemicals. This strength is vital for applications requiring durability. Polypropylene, though similar, lacks the same low-temperature flexibility. PVC is sturdier, but it can be more rigid and less adaptable. Polyethylene provides a balanced option for many needs.

Tips: Always assess the specific requirements of your project. Take into account factors like weather exposure and chemical interaction. Consider using recycled polyethylene to minimize environmental impact. This choice can contribute positively to your project and reduce waste. Re-evaluate your options regularly. Sometimes, what worked before may not suit your current needs. Don’t hesitate to experiment with different types of plastics for better results.

This chart compares the material strength of various types of plastics, highlighting polyethylene's competitive strength in comparison to polypropylene, PVC, and polystyrene. Choosing the right material based on strength can significantly impact your project's durability and performance.

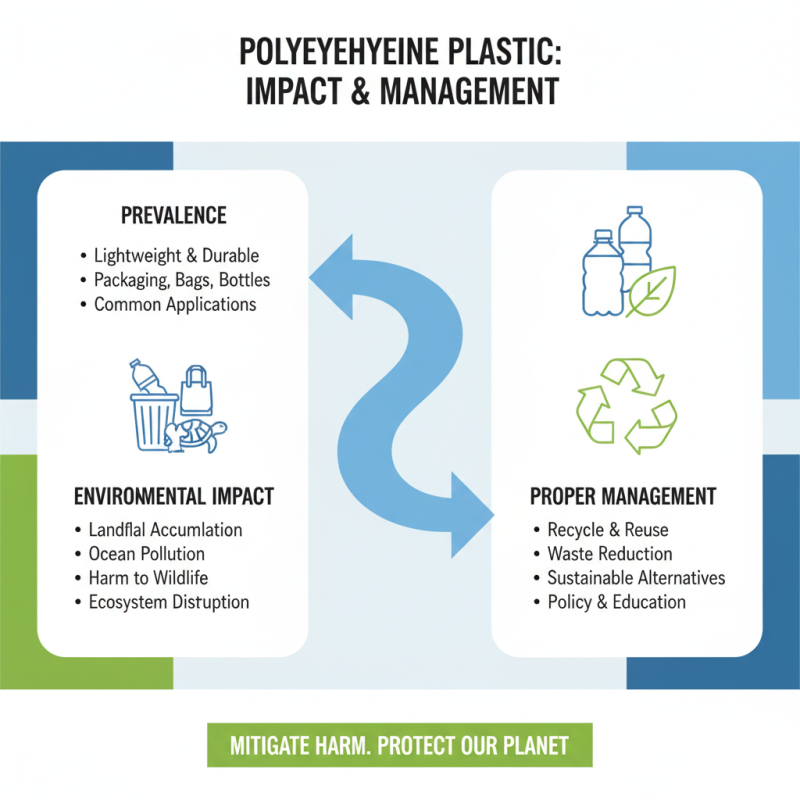

Polyethylene plastic is prevalent in various applications. Its lightweight and durable nature make it a popular choice. However, its environmental impact often raises questions. When disposed of improperly, polyethylene can accumulate in landfills and oceans. This not only harms wildlife but also disrupts ecosystems. Proper management is crucial to mitigating these effects.

Recycling polyethylene plastic offers a solution. Many facilities accept it, transforming it into new products. This reduces waste and conserves resources. Yet, not all polyethylene is recycled efficiently. Contamination can hinder the process. People often overlook the importance of rinsing before disposal. Simple actions can enhance recycling rates and minimize environmental damage.

While polyethylene has benefits, awareness is key. Advocating for better recycling practices is essential. Communities need education on proper disposal methods. Encouraging responsible production and consumption habits can pave the way for a more sustainable future.

When considering polyethylene plastic for your next project, it’s essential to evaluate key factors. Polyethylene is versatile and commonly used in various applications. Its resistance to moisture makes it suitable for both indoor and outdoor use. However, one must think about its durability for specific environments. Not every type will perform well in extreme weather conditions.

The intended application often dictates the type of polyethylene to choose. Low-density polyethylene (LDPE) is flexible and ideal for bags and films, while high-density polyethylene (HDPE) is tougher, great for containers and pipes. Think about what you need. Will it hold weight? Is flexibility necessary? These questions matter. It's also wise to consider environmental impacts. Recycling options and the source of materials can affect decision-making.

Color and texture might seem trivial but can impact aesthetics and functionality. Clear versus opaque, rough versus smooth surfaces—these choices should align with your project goals. Sometimes, managing expectations is crucial. Not every polyethylene type is perfect for every situation. Each project brings its challenges. Reflecting on these factors helps in making informed, effective choices while working with polyethylene.