When embarking on a project that requires durable materials, selecting the correct thick plastic roll is crucial. According to industry expert Dr. Sarah Thompson, "Choosing the right thickness can make all the difference in durability and usability." A thick plastic roll serves a wide range of applications, from construction to packaging.

Understanding your project's specific needs is vital. Consider factors like exposure to elements and load capacity. High-quality thick plastic rolls can withstand harsh conditions. However, not all plastic is equal. It’s important to evaluate the options available in the market.

There are many choices, but the right one can be elusive. Many people overlook the importance of thickness. This oversight often leads to issues down the line. Therefore, taking the time to analyze your requirements can save you from frustration. A thoughtful selection process is essential in achieving the desired results.

When choosing thick plastic rolls, understanding the various types is essential. Typically, you’ll find rolls made from polyethylene, polypropylene, and PVC. Each type serves different purposes, which influences your project’s success. Polyethylene is known for its flexibility. It's great for light-duty applications. On the other hand, PVC is strong and durable, making it fit for heavyweight tasks.

When selecting a roll, consider the thickness. A thicker roll can offer better protection. However, it may be harder to work with. Think about your project's requirements, such as weight and exposure to elements. Are you looking for something waterproof? Check the specifications carefully.

Tips: Always measure your workspace before making a purchase. This can save you from unwanted cuts and wasted material. Don’t overlook the importance of UV resistance. It can prolong the life of your project. Experimenting with smaller rolls can lead to better outcomes. Test how each type behaves before making a large commitment.

When selecting a thick plastic roll for your project, several key factors come into play. First, determine the thickness you need. Thicker materials offer durability, but can be harder to work with. If you choose a roll that's too thick, you may struggle during application. Consider your project’s demands and match the thickness accordingly.

Next, think about the material type. Not all plastic is created equal. Some are more resistant to weather conditions, while others may not hold up well outdoors. Understand where you will use the plastic. If it’s for a temporary cover, lighter materials may suffice. For long-term use, opt for something sturdier.

Lastly, examine the finish of the plastic. A smooth surface may appeal for certain applications, while a textured one could enhance grip or adhesion. Choosing the wrong finish can lead to problems. Check specifications carefully. Keep in mind the cost as well. While you want quality, overspending may lead to regret later. Balancing budget and requirements is crucial, and sometimes compromises must be made.

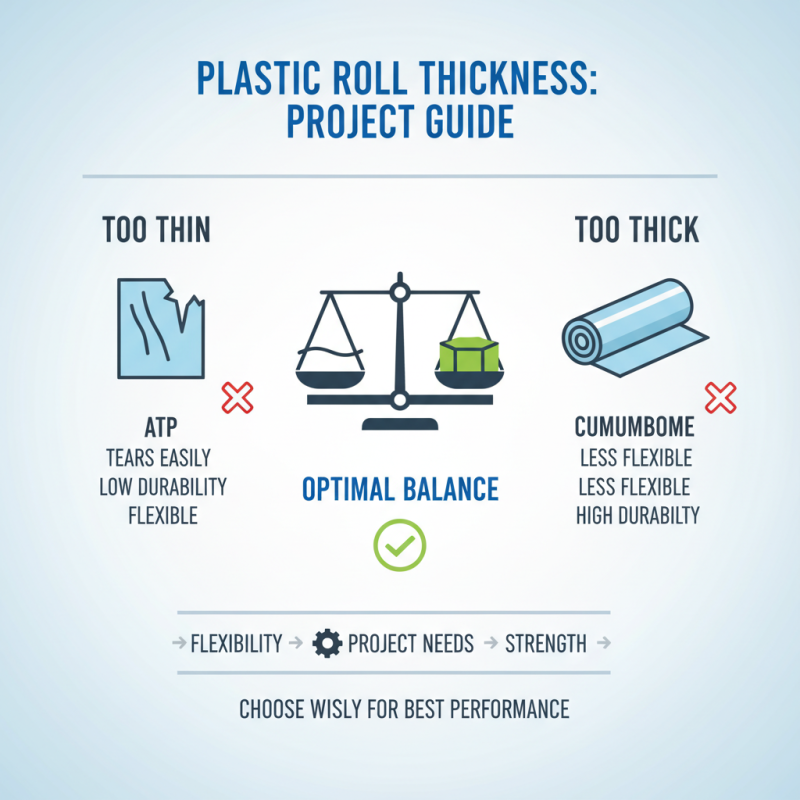

When choosing a thick plastic roll for your project, thickness and durability are crucial factors. The thickness of plastic can impact its performance in various applications. A roll that is too thin may tear easily. Conversely, overly thick material can be cumbersome and less flexible. It’s important to balance these aspects based on your specific needs.

Consider the environment in which the plastic will be used. If it’s subject to harsh weather or physical stress, durability becomes essential. For example, outdoor projects may require a thicker, more resilient plastic. However, using heavy-duty plastic indoors may be unnecessary and could lead to waste. Reflect on the conditions and choose accordingly.

Remember that not all thick plastic rolls offer the same durability. Investigate the materials used and their specific properties. Some might look robust but fail under pressure. It’s a common oversight to assume that thickness guarantees strength. Testing samples before committing could save time and resources.

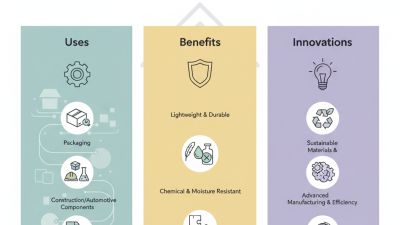

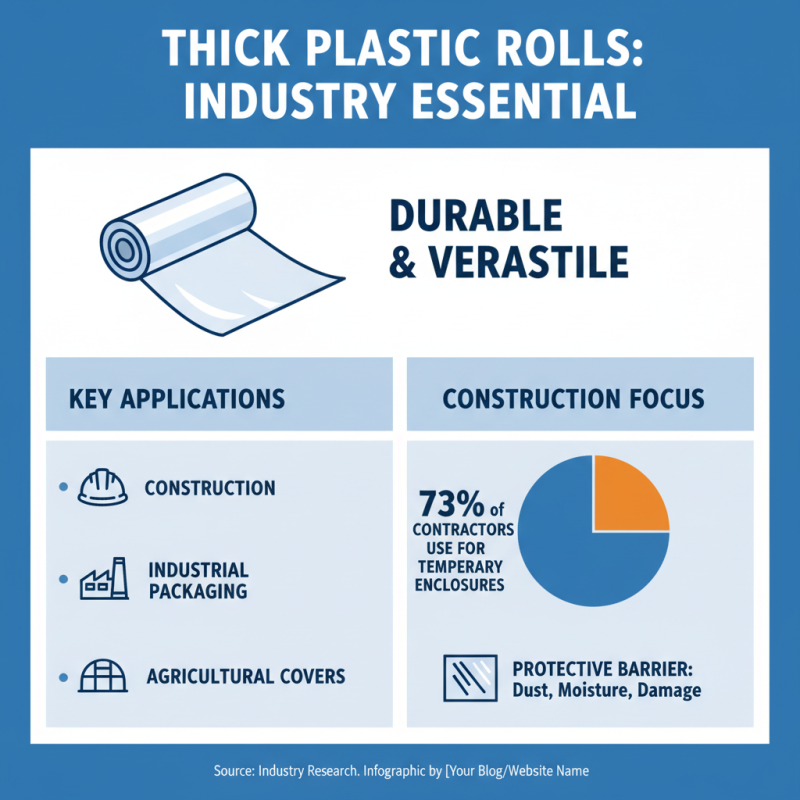

Thick plastic rolls are vital in many industries. Their durability and versatility enable a wide range of applications. For construction, these materials can serve as protective barriers. They shield surfaces from dust, moisture, and damage. According to industry research, 73% of contractors use thick plastic rolls for temporary enclosures.

In agriculture, these rolls offer valuable protection for crops. They help regulate temperature and humidity. Studies show that greenhouses with thick plastic barriers see a 25% increase in yield. This is significant for farmers seeking efficiency. Additionally, the automotive sector uses these materials for car coverings. They protect vehicles during transit.

However, not all thick plastic rolls are created equal. Some may not have the necessary UV resistance. This can lead to failures in long-term projects. It's essential to assess individual project needs carefully. Understanding specifications will lead to better choices. Each application may require different thicknesses or qualities. Proper evaluation is key to project success.

When budgeting for thick plastic rolls, consider your project needs and quality. Prices can vary greatly based on thickness, size, and type. Assess the total area you need to cover. This helps avoid overspending on excess material. Effective planning can save money.

If possible, get multiple quotes. Comparing suppliers can highlight significant price differences. Don’t forget to factor in shipping costs. Discounts for bulk orders may exist. This can further reduce expenses while meeting project demands.

Tip: Always calculate material waste. Sometimes, excess purchases lead to unnecessary costs. Use proper measurements before placing any order. Keep an eye out for sales and seasonal promotions. Allocating funds wisely ensures you maximize your budget while achieving your project goals.