Polypropylene sheets are increasingly recognized for their versatility and durability across various industries, offering a lightweight yet strong material solution for diverse applications. According to the latest report from Smithers Pira, the global market for polypropylene is projected to grow at a CAGR of 4.1%, reaching approximately $350 billion by 2025. This surge in demand highlights the importance of understanding the different types of polypropylene sheets available in the market and their suitability for specific projects.

When selecting the best polypropylene sheet, factors such as thickness, color, surface texture, and weight must be considered to ensure optimal performance and compatibility with the desired application. Industry standards, such as those set by ASTM International, provide guidelines on the mechanical and thermal properties of polypropylene sheets, which can influence decisions regarding product selection. In sectors ranging from packaging to construction, the right polypropylene sheet can significantly enhance product effectiveness and longevity, making informed choices essential for project success. Understanding these facets will empower professionals to make strategic decisions that align with their project requirements.

Polypropylene sheets are versatile plastic materials used in a wide array of applications, and understanding their types and characteristics is essential in selecting the right one for your projects.

Primarily, there are two main types of polypropylene sheets: homopolymer and copolymer.

Homopolymer sheets possess rigidity and are typically used for applications that require strength. In contrast, copolymer sheets exhibit increased impact resistance and flexibility, making them ideal for uses that require durability in more demanding conditions.

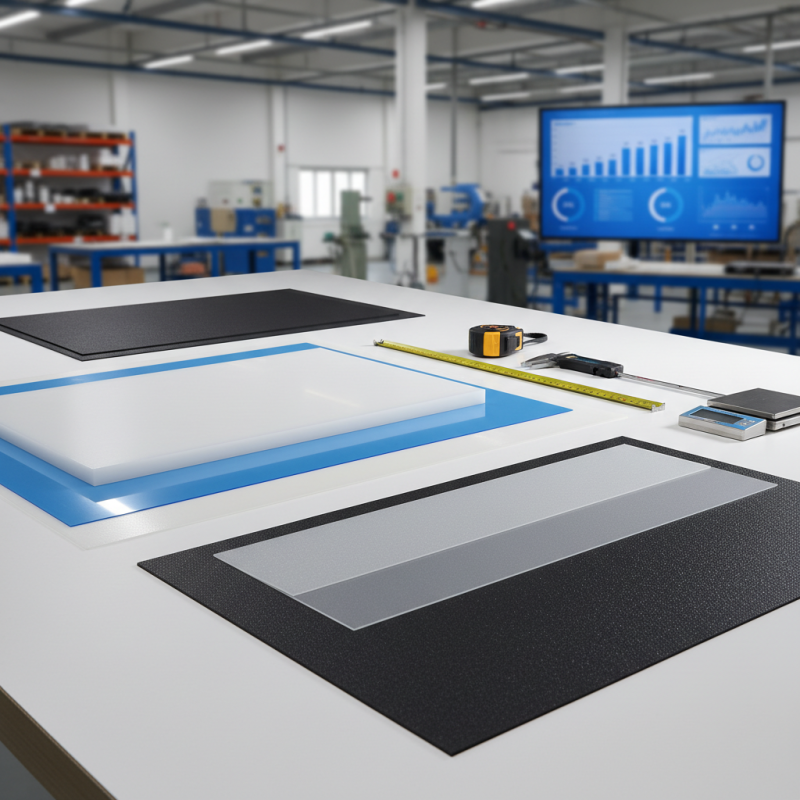

When assessing the characteristics of polypropylene sheets, factors such as thickness, color, and surface finish play a crucial role. Thicker sheets provide enhanced structural integrity and durability, while varying colors allow for aesthetic customization in design projects. The surface finish can be matte, glossy, or textured, which not only affects the visual appeal but also influences functionality, particularly in applications requiring adhesion or printing.

By understanding these types and characteristics, you can make an informed choice that aligns with your project's specific requirements.

When selecting polypropylene sheets for your projects, several key factors warrant careful consideration to ensure you choose the best material for your needs. First and foremost, assess the thickness of the sheets. Thicker sheets typically offer greater strength and durability, making them suitable for heavy-duty applications. Conversely, if your project requires flexibility and ease of handling, thinner sheets may be more appropriate. Always consider the specific requirements of your application to match the sheet thickness accordingly.

Another crucial factor is the sheet's chemical resistance. Polypropylene sheets are known for their resistance to a wide range of chemicals, making them ideal for various industrial and laboratory applications. Evaluate the substances that the sheets will be exposed to and verify that the specific grade of polypropylene chosen can withstand those chemicals without compromising integrity.

Tips: When you're in doubt about the specific type of polypropylene sheet that will best suit your project, consult with suppliers or professionals who are experienced in material selection. Additionally, consider the environmental conditions to which the sheets will be subjected, such as temperature ranges and exposure to UV light, as these can influence the longevity of the material.

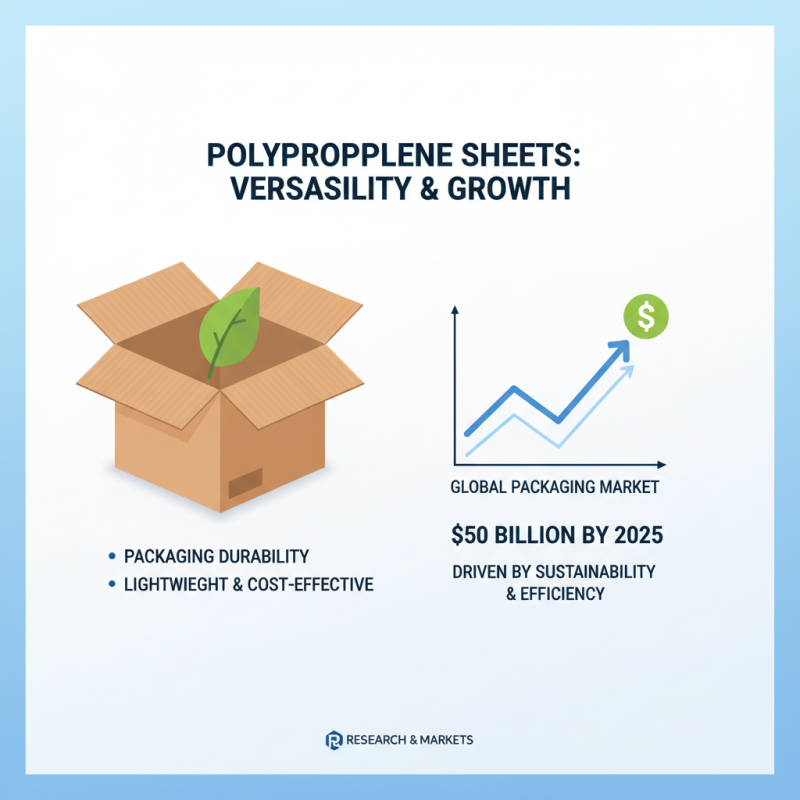

Polypropylene sheets are increasingly recognized for their versatility across various industries. In the packaging sector, they are often used due to their lightweight yet durable nature, allowing for effective protection of products while reducing shipping costs. According to a recent market report by Research and Markets, the global polypropylene packaging market is projected to reach $50 billion by 2025, driven by the demand for cost-effective and sustainable packaging solutions. This increase underscores the importance of polypropylene sheets in creating reliable and eco-friendly packages.

In the construction industry, polypropylene sheets serve multiple purposes, from moisture barriers to insulation materials. Their resistance to chemicals and humidity makes them ideal for applications in both residential and commercial buildings. A report by MarketsandMarkets indicates that the demand for polypropylene in construction is expected to grow at a CAGR of 5.5% and reach approximately $9 billion by 2024. This growth can be attributed to the material's strength and long-lasting properties, making it a preferred choice for builders looking for cost-effective building materials that do not compromise on quality. Thus, the applications of polypropylene sheets continue to expand, showcasing their critical role in modern industrial applications.

When selecting materials for a project, understanding the properties of polypropylene sheets in comparison to other sheet materials is crucial.

Polypropylene stands out for its excellent chemical resistance, lightweight nature, and ease of fabrication. Unlike materials such as acrylic, which can be brittle and prone to shattering, polypropylene offers a more durable option that withstands impact without compromising on clarity. Moreover, its resistance to moisture makes it ideal for applications in humid environments.

In contrast, while polyethylene is also durable, it lacks the rigidity and temperature resistance that polypropylene provides, making it less suitable for applications requiring structural integrity. Additionally, materials like PVC, although cost-effective, can have limitations in terms of flexibility and environmental impact.

Polypropylene's recyclability and lower environmental footprint present advantages for eco-conscious projects. By comparing these characteristics, one can better determine how to leverage the unique properties of polypropylene sheets to enhance project outcomes, ensuring the right choice based on specific application needs.

When sourcing quality polypropylene sheets for your projects, it's essential to consider multiple factors that can impact performance and durability. According to a recent market analysis by Grand View Research, the global polypropylene market was valued at approximately $114 billion in 2021, and it is projected to grow at a compound annual growth rate (CAGR) of 5.7% from 2022 to 2030. This growth signifies an increasing demand for high-quality materials, and knowing how to choose the right polypropylene sheet can make a significant difference in the outcome of your project.

First and foremost, assess the specific requirements of your project, such as thickness, tensile strength, and clarity. Polypropylene sheets are available in various grades, each tailored to different applications. For instance, some sheets are designed for high-impact resistance, while others focus on chemical resistance. According to data from Smithers, the global demand for custom-engineered plastics, including polypropylene, has surged as industries seek lightweight materials that can withstand harsh environments. This trend underscores the importance of sourcing sheets that meet rigorous quality standards, ensuring they can perform effectively under the anticipated conditions.

Additionally, consider the sourcing practices of your suppliers. Opting for manufacturers who adhere to recognized quality assurance standards, such as ISO certifications, can provide peace of mind regarding the reliability of the materials. This diligence not only supports the integrity of your projects but also aligns with sustainability practices; many organizations are now focusing on environmentally friendly production methods. By prioritizing quality and sustainability during the sourcing process, you can ensure that the polypropylene sheets you select will not only meet your project's needs but also contribute positively to market trends supporting environmentally responsible practices.