When embarking on a project that requires durable and reliable materials, choosing the right thick plastic sheets can make a significant difference in the overall success and longevity of your work. According to industry expert Dr. Emily Harper, a leading authority in plastic materials, “Selecting the appropriate thickness and type of plastic sheet can enhance the performance of your project while ensuring cost-effectiveness.” This sentiment underscores the importance of understanding the specific requirements of your project and the characteristics of thick plastic sheets available in the market.

Thick plastic sheets come in various materials, each offering unique properties suited for different applications. Whether you are working on a construction project, creating custom signage, or need protective barriers, the choices can be overwhelming. However, by considering factors such as weight, impact resistance, and environmental conditions, you can narrow down your options effectively. Dr. Harper emphasizes that “the right choice not only improves functionality but also contributes to the aesthetic appeal of the finished product.” Therefore, an informed selection process is vital for achieving your desired outcomes.

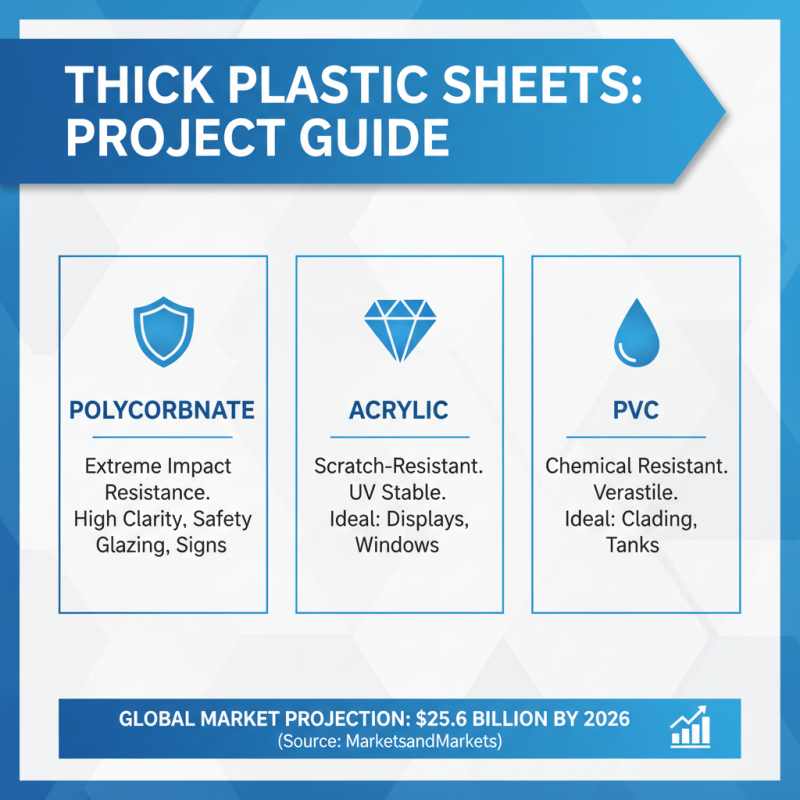

When selecting thick plastic sheets for your project, it's essential to understand the various types available in the market. Common materials include polycarbonate, acrylic, and PVC, each offering unique characteristics tailored for specific applications. According to a report by MarketsandMarkets, the global plastic sheets market is projected to reach 25.6 billion USD by 2026, with polycarbonate sheets witnessing significant growth due to their high impact resistance and clarity, making them ideal for safety-glazing and signage.

Acrylic sheets, known for their excellent optical clarity and weather resistance, are another popular option. They provide a lightweight alternative to glass, making them suitable for applications such as aquariums and display cases. The American Plastics Council notes that the demand for acrylic sheets has surged by 4.5% annually, reflecting their versatility in both indoor and outdoor settings. On the other hand, PVC sheets, with their chemical and corrosion resistance, are often utilized in construction and industrial applications, further highlighting the need to consider the intended use when choosing thick plastic sheets for your projects.

When evaluating the strength and durability requirements for your project, it's crucial to consider the specific demands of your application. Thick plastic sheets come in various materials, each offering different properties that affect performance. For instance, polycarbonate sheets boast an impressive impact resistance, rated 200 times stronger than glass, making them suitable for high-stress environments such as construction sites or safety glazing. According to a report by the Plastics Industry Association, polycarbonate can withstand temperatures ranging from -40°F to 250°F, ensuring durability in extreme conditions.

Moreover, the thickness of the plastic sheet plays a significant role in its overall strength and rigidity. Materials like acrylic are lightweight yet provide excellent clarity and resistance to UV degradation, commonly used in applications that require long-term exposure to sunlight. The same report highlights that sheets with a thickness of 0.25 inches or more can resist warping and maintain structural integrity for extended periods. Hence, carefully evaluating your project's environmental challenges—such as exposure to chemicals, temperature fluctuations, and physical impact—will help in selecting the right thick plastic sheet that aligns with durability benchmarks essential for your intended use.

When selecting thick plastic sheets for a project, it's essential to assess the environmental conditions that will affect their performance and longevity. Various factors such as temperature fluctuations, exposure to UV radiation, moisture levels, and potential chemical exposure play a critical role in determining the most suitable type of plastic. For example, if the sheets will be used in outdoor applications, materials with UV resistance are imperative to prevent degradation over time. Similarly, areas with high humidity or constant moisture might require plastic sheets with superior water resistance to avoid warping or mold growth.

Additionally, consider the specific physical demands placed on the plastic sheets in their intended environment. Heavy loads or impact resistance might necessitate thicker, more durable materials, while flexibility could be a requirement for applications where the sheets must conform to various shapes. Conducting a thorough evaluation of these environmental conditions will help ensure that the chosen plastic sheets not only meet aesthetic and functional requirements but also endure the expected wear and tear, resulting in a successful and sustainable project outcome.

When selecting thick plastic sheets for your project, one of the most significant factors to consider is your budget. The cost of these materials can vary widely depending on the type of plastic, thickness, and dimensions. Generally, materials like acrylic and polycarbonate are more expensive than PVC, but they may offer better durability and transparency. It’s crucial to evaluate not just the price per sheet, but also the long-term savings associated with durability - a higher upfront investment may lead to lower replacement costs over time.

Additionally, you need to account for the total quantity required and any potential waste during installation. Some manufacturers offer bulk purchasing options that can significantly reduce costs if you need large panels or multiple sheets. It’s wise to calculate your total expenditure by including shipping and any additional fees such as cutting or customization. By understanding the various factors influencing the cost of thick plastic sheets, you can make a more informed decision that aligns with your financial constraints while meeting the specific requirements of your project.

When selecting thick plastic sheets for various projects, it's crucial to identify their specific applications and uses to ensure optimal performance. Thick plastic sheets, often made from materials like acrylic, polycarbonate, or PVC, are widely utilized across multiple industries. According to industry reports, the global demand for plastic sheets is expected to rise, driven by their versatility in sectors such as construction, automotive, and manufacturing. For instance, acrylic sheets are frequently chosen for their clarity and UV resistance, making them ideal for signage and protective barriers.

In construction, thick plastic sheets serve as effective solutions for insulation and weatherproofing. They provide an airtight seal, enhancing energy efficiency in buildings. Data from the Plastic Industry Association shows that the construction sector accounts for approximately 20% of the total plastic sheet consumption, highlighting the substantial role plastic plays in modern structures. Additionally, in the manufacturing sector, thick plastic sheets are used in fabricating custom parts and components due to their strong impact resistance and ease of machining. The versatility of these sheets allows for applications ranging from safety shields in industrial environments to customizable display cases in retail settings, underscoring the importance of carefully considering the material properties for each specific project requirement.