In the fast-evolving world of manufacturing, mastering plastic fabrication techniques is essential for enhancing the quality and efficiency of projects. This versatile process plays a crucial role in countless industries, from automotive to healthcare, providing innovative solutions that meet the demands of modern design and functionality. As the use of plastic continues to grow, understanding effective fabrication techniques can significantly impact the performance and prominence of your projects.

Whether you are a seasoned professional or a newcomer to the field, implementing the right strategies in plastic fabrication can lead to remarkable improvements. This article presents the top ten tips for effective plastic fabrication that can help streamline your workflow, minimize waste, and elevate the overall quality of your end products. By embracing these techniques, you can unlock the full potential of plastic as a material, allowing for creative and efficient designs that stand out in a competitive market.

Understanding the fundamentals of plastic fabrication materials and tools is crucial for achieving quality results in your projects. Various types of plastics, including acrylic, polycarbonate, and PVC, possess unique properties that make them suitable for different applications. Acrylic, for instance, is known for its clarity and ease of fabrication, making it a popular choice for display cases and signage. Polycarbonate, on the other hand, offers excellent impact resistance, making it ideal for environments where durability is a priority. Understanding these material properties allows fabricators to select the appropriate plastic based on the specific requirements of their project.

In addition to materials, familiarity with the right tools is essential for effective plastic fabrication. Common tools used in this field include CNC routers, laser cutters, and heat guns, each serving a distinct purpose. CNC routers provide precision cutting for complex designs, while laser cutters offer clean edges with minimal finishing required. Heat guns are useful for bending and shaping plastics, allowing for versatile designs. Having a solid grasp of these tools and their applications enables fabricators to achieve enhanced accuracy and efficiency, ultimately leading to improved project outcomes. The combination of selecting the right materials and utilizing proper tools lays the groundwork for successful plastic fabrication techniques.

Precision in cutting and shaping plastic is crucial for successful fabrication in various industries, including automotive, aerospace, and consumer goods. Recent data from the Plastics Industry Association highlights that the U.S. plastics market is expected to reach $370 billion by 2024, underscoring the need for effective techniques that enhance project outcomes. Techniques such as laser cutting, CNC machining, and waterjet cutting are vital for achieving accuracy and efficiency in plastic fabrication. Laser cutting, for instance, offers clean edges and reduced material waste, making it an ideal choice for intricate designs and thin materials.

In addition to cutting, shaping techniques such as thermoforming and injection molding are critical for producing consistent and high-quality plastic products. Thermoforming allows manufacturers to create complex shapes with minimal material loss, while injection molding provides rapid production capabilities, essential for high-volume projects. According to a report by Grand View Research, the global injection molding market is projected to grow at a CAGR of 5.7% from 2021 to 2028, driven by innovations in material science and production technologies. By adopting these precise techniques, fabricators can optimize their workflows, reduce costs, and improve the overall quality of their finished products.

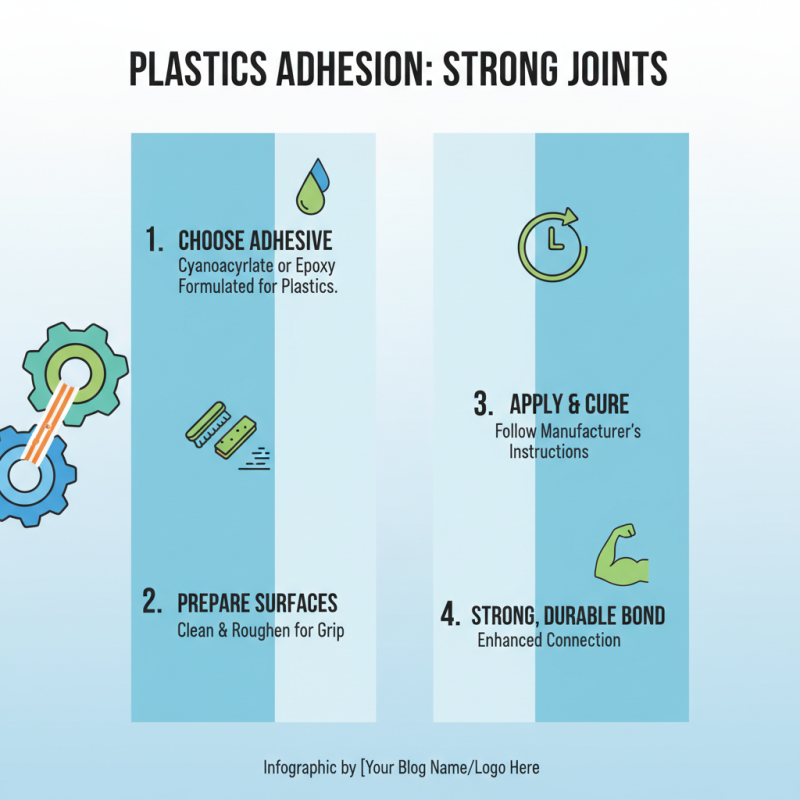

When it comes to joining and assembling plastic components, selecting the right technique is paramount for achieving strong and durable connections. One effective method is the use of adhesives specifically formulated for plastics. These adhesives, such as cyanoacrylate or epoxy resins, provide excellent bonding characteristics and can accommodate different types of plastic materials. It is essential to prepare the surfaces properly by cleaning and possibly roughening them to enhance adhesion. Additionally, following the manufacturer's instructions regarding curing times and application methods plays a crucial role in the overall strength of the joint.

Mechanical fastening is another reliable approach to assembling plastic components. Techniques such as bolting or using screws designed for plastic can allow for adjustable and disassemble-friendly connections. Pre-drilling holes to prevent cracking or splitting is crucial when using mechanical fasteners. Furthermore, incorporating alignment features, such as tabs or interlocking designs, can facilitate precise assembly and enhance the structural integrity of the final assembly. Each method has its advantages, and understanding the specific requirements and properties of the materials involved allows for informed decisions that lead to successful projects.

In the field of plastic fabrication, maintaining safety standards is of paramount importance. According to a report by the Occupational Safety and Health Administration (OSHA), workplace safety incidents can lead to significant financial losses, amounting to over $1 billion annually in the manufacturing sector due to injuries. This highlights the necessity for stringent safety measures in plastic fabrication processes, where workers may be exposed to hazardous materials and machinery.

To uphold safety standards, it is essential to implement comprehensive training programs for all employees. A study published in the Journal of Safety Research revealed that over 70% of workplace accidents could be mitigated through proper education and awareness of safety protocols. Additionally, utilizing personal protective equipment (PPE) is vital. In fact, the National Institute for Occupational Safety and Health (NIOSH) recommends the use of PPE in environments where exposure to harmful substances is possible, emphasizing that it can reduce the risk of accidents by up to 40%.

Furthermore, regular maintenance of tools and equipment is crucial to ensure safe operation. A 2021 industry report indicated that 30% of machinery-related injuries stemmed from poorly maintained equipment. By adhering to a strict schedule of inspections and repairs, businesses can not only enhance safety but also improve overall productivity. In the realm of plastic fabrication, prioritizing safety standards is not just a regulatory requirement; it is an investment in the well-being of employees and the sustainability of operations.

| Tip Number | Technique | Description | Safety Considerations |

|---|---|---|---|

| 1 | Material Selection | Choose the right plastic material for durability and processing ease. | Ensure materials meet safety standards and are suitable for application. |

| 2 | Proper Tools | Use tools designed for plastic fabrication to avoid damage. | Regularly check tools for wear and tear to prevent injuries. |

| 3 | Temperature Control | Maintain optimal temperatures during fabrication processes to ensure quality. | Monitor temperature to avoid burns and hazardous fumes. |

| 4 | Cleaning Procedures | Keep workspaces and tools clean to prevent contamination. | Use non-toxic cleaning agents to ensure worker safety. |

| 5 | Proper Ventilation | Ensure adequate ventilation in the workspace during fabrication processes. | Prevent inhalation of fumes that may be harmful. |

| 6 | Personal Protective Equipment | Use goggles, gloves, and masks during fabrication. | Protect against sharp edges and hazardous materials. |

| 7 | Quality Control | Implement quality checks throughout the fabrication process. | Identify defects early to ensure safety and functionality. |

| 8 | Training Programs | Provide regular training for staff on safe fabrication practices. | Ensure all workers understand risks and safety measures. |

| 9 | Emergency Procedures | Establish clear emergency procedures for incidents during fabrication. | Train staff on how to respond in emergencies. |

| 10 | Continuous Improvement | Regularly review and refine fabrication processes. | Adapt to new safety regulations and technology. |

In the realm of plastic fabrication, achieving aesthetic excellence is as crucial as ensuring structural integrity. Innovative finishing techniques serve not only to enhance the visual appeal of projects but also to elevate their marketability. According to a report by Grand View Research, the global plastic fabrication market is projected to reach $830 billion by 2027, largely driven by consumer preferences leaning towards aesthetically appealing products. This emphasizes the significance of incorporating finishing techniques that go beyond mere functionality.

Techniques such as acrylic coating, laser engraving, and CNC machining play vital roles in enhancing the surface textures and colors of plastic components. For instance, laser engraving not only allows for intricate designs but also enables customization possibilities that meet diverse consumer tastes. The latest industry studies suggest that products featuring high-quality finishes can command up to 30% higher market prices, indicating that aesthetic enhancements can directly influence profitability. Moreover, adopting eco-friendly finishing options, such as water-based paints and biodegradable coatings, can attract environmentally conscious consumers. Thus, incorporating innovative finishing techniques is not just about attraction—it's a strategic move that aligns with market trends and sustainability goals.