Vacuum molding is a fascinating technique used in various industries. It allows for the creation of multiple shapes and designs with precision. Beginners often feel overwhelmed by the complexities involved. However, mastering vacuum molding is achievable with practice and the right guidance.

Understanding the basics is crucial. Choose the right materials for your projects. Each material reacts differently during the process. You may face setbacks, but these moments are learning opportunities. Experimenting with different settings can lead to unexpected results. This process may seem daunting at first, but patience is key.

Mastering vacuum molding involves both skill and creativity. It is important to establish a workspace that fosters innovation. Track your progress. Reflect on what works and what doesn't. Embrace imperfections; they are part of the learning curve. With these tips, you'll uncover the potential of vacuum molding and create impressive designs along the way.

Vacuum molding is a fascinating process. It involves shaping plastic sheets using heat and vacuum power. Understanding this technique is essential for beginners. According to industry studies, the global market for vacuum molding grew by 5% annually. This suggests increasing demand for versatile manufacturing methods.

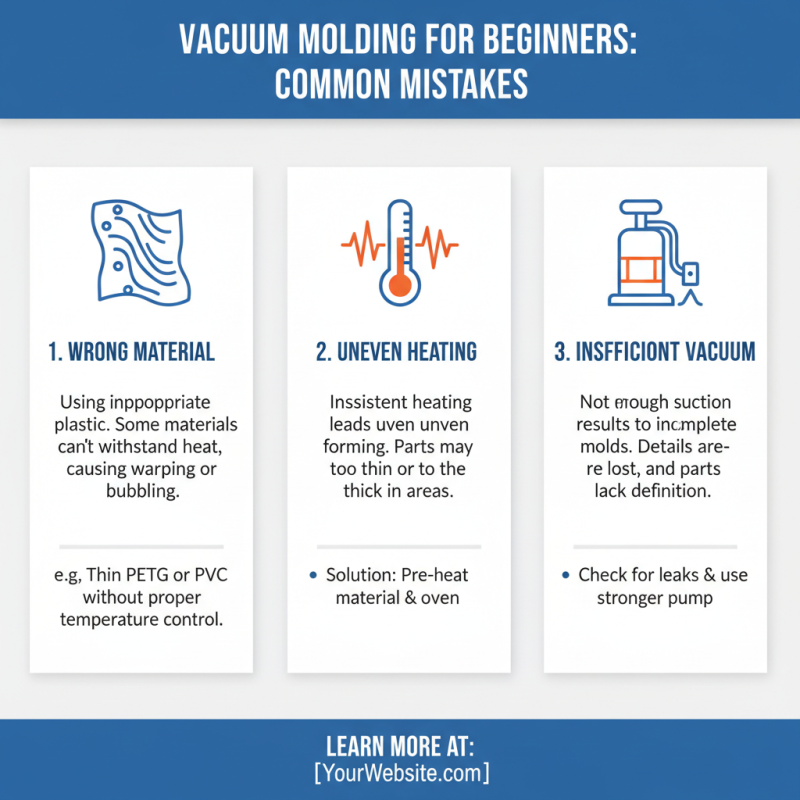

Newcomers often face challenges with temperature control. Too hot, and the plastic becomes unusable. Too cool, and it won’t mold properly. It's crucial to find that balance. Another common pitfall is inconsistent pressure during the vacuum phase. A 2022 report indicated that 30% of beginners reported issues with uneven vacuum pressure. This leads to defects, wasting both time and materials.

Prepping the mold is vital for success. Ensure the mold surface is smooth to achieve a polished finish. Regular practice can help refine this skill. Additionally, using the right materials can make a significant difference. Selecting high-quality plastic will yield better results. Embracing mistakes can also foster growth. Reflecting on errors allows for improvement, turning them into valuable learning experiences.

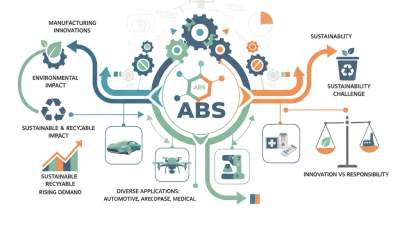

Vacuum molding is a popular technique used for various applications, from prototyping to manufacturing. To achieve success, you must focus on essential tools and materials. Accurate selection can make a significant difference in the final output. Reports show that nearly 70% of failures in vacuum molding stem from improper material choice and mold preparation.

One crucial tool is the vacuum pump. A high-quality pump ensures optimal air removal, which is key to achieving smooth and precise molds. Research indicates that using pumps with a flow rate appropriate for your material's volume can enhance efficiency. Additionally, investing in a reliable heating element is vital for reaching the necessary temperatures for different thermoplastics. The right material, such as ABS or PVC, can profoundly affect the mold’s durability. Each material has unique properties, and choosing the wrong one can lead to warping or incomplete forms.

Don't overlook surface preparation materials. Silicone sprays or mold release agents can help achieve clean demolding. Some beginners underestimate their importance, leading to errors and wasted resources. Remember, experimenting with different materials and tools takes time. Keep a record of your projects; this reflection will guide you on adjustments needed for future work. The journey of mastering vacuum molding is often circuitous, and learning from each attempt is crucial.

Setting up vacuum molding equipment can seem daunting. However, with a clear process, beginners can get started smoothly. First, ensure you have all necessary components. This includes the vacuum pump, mold, and heat source. Organize these items in one location for easy access.

Also, consider the workspace. It should be clean and well-ventilated. Dust and debris can ruin your molding projects. When preparing your mold, use a releasing agent to prevent sticking. This small step saves a lot of frustration later.

Tip: Always check the vacuum levels before starting. Too low can lead to imperfections. Keep an eye on the temperature of your materials as well. Overheating can affect your final product's quality. Mistakes will happen, but they are valuable learning experiences. Reflect on what went wrong. Adjust your technique accordingly for better results next time.

| Tip Number | Tip Description | Benefits |

|---|---|---|

| 1 | Choose the Right Materials | Ensures compatibility and quality of the final product. |

| 2 | Set Up a Proper Workspace | Increases efficiency and minimizes errors during molding. |

| 3 | Calibrate Your Vacuum Pump | Improves the molding precision and reduces air pockets. |

| 4 | Invest in High-Quality Molds | Enhances the durability and surface finish of the parts. |

| 5 | Maintain Consistent Heating | Ensures uniformity in the molding process and reduces defects. |

| 6 | Practice Proper Timing | Optimizes the cycle time and productivity of the operation. |

| 7 | Test with Samples First | Allows for adjustments before final production, reducing waste. |

| 8 | Ensure Proper Venting | Prevents trapped air, allowing for better mold filling. |

| 9 | Clean Equipment Regularly | Maintains equipment performance and extends lifespan. |

| 10 | Learn from Mistakes | Improves skills and knowledge for future projects. |

Vacuum molding can be challenging for beginners. Understanding common mistakes is essential for success. One common error is using the wrong material. Choosing an inappropriate plastic can lead to poor results. For instance, some plastics may not withstand the heat properly. This can cause warping or bubbling in your final product.

Another frequent issue is improper mold sealing. If the mold isn’t sealed well, air can escape. This can create defects in your shape. It is vital to check seals before starting the process. Additionally, beginners often rush the heating phase. Not allowing enough time for the material to soften can lead to uneven molds. Always monitor heating closely.

Lastly, neglecting post-processing can result in unsatisfactory finishes. Many newcomers overlook sanding or trimming. Ignoring these steps leaves imperfections on the surface. Reflecting on these aspects can help in honing skills. Recognizing flaws will improve future projects.

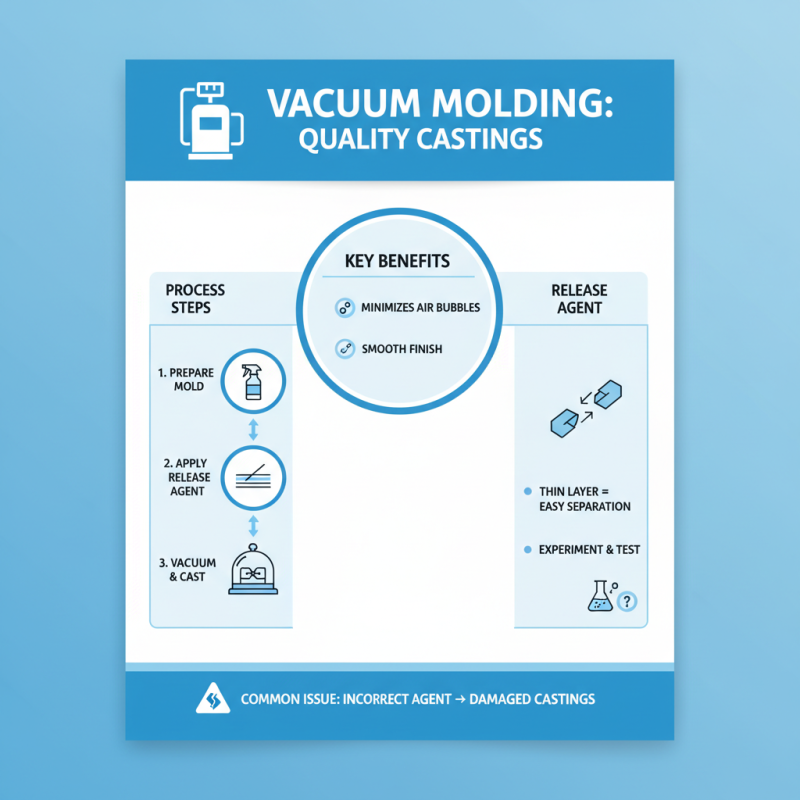

Vacuum molding can produce high-quality molds and castings if done right. The vacuum process minimizes air bubbles. This is vital for a smooth finish. Use a proper release agent. A thin layer ensures easier separation of your mold from the material. Experimenting with different agents can yield varied results. Sometimes, the chosen release agent may not work as intended, leading to damaged casts.

Temperature control plays a crucial role. Materials often react differently under various temperatures. Too hot? The mold may warp. Too cold? The casting could have surface defects. Take notes during your molding experiments. Document what works and what doesn’t. This will help refine your technique over time.

Materials are equally important. Different plastics behave differently under vacuum conditions. Some are more forgiving, while others are a challenge. Learn through practice. You may face failures; don't get discouraged. Every mistake teaches you something new. Pay attention to detail with each casting. Measure and mix carefully to avoid inconsistencies. This meticulous approach can lead you to more successful outcomes.