Extrusion machines play a vital role in multiple industries today. They transform raw materials into useful products through a process of continuous shaping. According to Dr. John Thompson, an expert in polymer technology, "Extrusion machines are the backbone of modern manufacturing." This statement highlights the significance of these machines in producing consistent and high-quality materials.

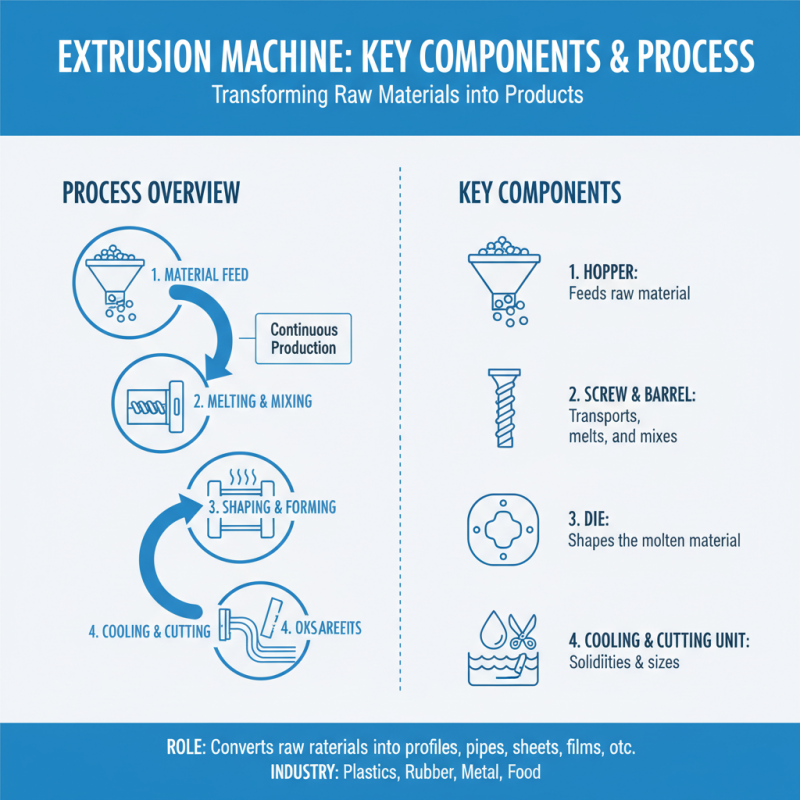

Understanding how an extrusion machine works is essential. It uses heat and pressure to mold materials into desired forms. This method applies to plastics, food, and even metals. The process involves feeding raw material into a hopper, which then moves through a heated barrel. As it travels, the material gets mixed, melted, and forced through a die. It's a fascinating interplay of physics and engineering.

However, some challenges exist in the extrusion process. The precision required can be difficult to achieve. Miscalibrations lead to defects in the final product. Continuous monitoring is critical for maintaining quality. Each step needs to be meticulously checked. If not, inefficiencies may arise, causing waste. The learning journey with extrusion machines often requires reflection and adjustment for success.

An extrusion machine is a vital tool in manufacturing. It transforms raw materials into products with consistent shapes. The process involves forcing material through a die to create a desired profile. This method is widely used in industries like plastic, food, and metal.

These machines serve various purposes. They produce items such as pipes, sheets, and profiles. The extrusion process is efficient, often yielding high output rates. Operators must monitor temperature and pressure closely. A small change can lead to defects. This requires attention to detail and a deep understanding of how materials behave under stress.

Despite their benefits, extrusion machines are not without challenges. Common issues include material jams or variations in thickness. These problems can cause delays and increase waste. Operators often reflect on their processes to improve efficiency. Continuous learning and adaptation are essential for success in this field.

Extrusion machines play a critical role in the manufacturing industry. They transform raw materials into specific shapes and sizes through a continuous process. Key components drive this process effectively.

The feeder, for example, ensures a consistent supply of raw materials. It regulates the flow into the barrel. A report from the Plastics Industry Association indicates that inconsistencies here can lead to defective products. The heating system warms the material as it travels through the barrel. Temperature control is crucial, as improper heating affects the material's properties.

Another essential part is the screw, which mixes and pushes the material forward. According to industry data, the screw design significantly impacts efficiency and product quality. The die shapes the final product. A poorly designed die can lead to material waste and increased costs. Even veteran operators can struggle with setup, leading to variability in production quality. Balancing these components requires attention and regular adjustments.

The extrusion process consists of several key steps that transform raw materials into durable products. Initially, raw materials like plastic pellets are fed into the machine. The feeding system ensures a steady flow into the heating chamber. Here, the pellets are subjected to heat and pressure, causing them to melt.

As the material melts, it is mixed thoroughly. This mixing ensures consistency in texture and quality. The melted material is then pushed through a die, which shapes it into a specific profile. This part of the process requires precision; any slight error can affect the final product's integrity. The speed needs careful monitoring since too fast may lead to defects.

Cooling follows shape formation. This step is crucial as it solidifies the product. Typically, cooling involves water or air, depending on the material type. After cooling, the extruded product is cut into desired lengths. However, operators face challenges in maintaining uniformity throughout the process. Small variations can lead to significant discrepancies in the final outcome. Continuous adjustments and quality checks are vital to address these issues effectively.

Extrusion machines are versatile tools used in various industries to shape materials. There are several types of extrusion machines, each serving unique applications. For instance, the

single-screw extruder is common in plastic processing. It offers a simple design and is effective for continuous production. However, it may struggle with certain materials that require precise temperature control.

On the other hand, twin-screw extruders provide better mixing and are ideal for compound formulations. They handle diverse materials, including polymers and food. Yet, they can be more complex and expensive to operate. Additionally, ram extruders are suitable for high-viscosity materials. They are often used in the production of ceramic or metal paste.

Despite their advantages, each machine type has limitations. The choice often depends on the specific application and desired output. It’s crucial to balance efficiency with material properties. Each application might not yield perfect results. Understanding these nuances can lead to better decision-making.

Extrusion machines play a crucial role in modern manufacturing. They are designed to convert raw materials into finished products through a process known as extrusion. This technology offers numerous advantages that enhance productivity and efficiency. According to industry reports, extrusion can reduce production costs by up to 30% compared to other methods.

One significant benefit is material efficiency. Extrusion machines can utilize a variety of materials, including plastics and metals, with minimal waste. Industry data shows that companies using extrusion achieve up to 85% material utilization rates. This not only boosts profitability but also contributes to sustainable practices. However, machine setup and calibration can be challenging, leading to initial production inconsistencies.

Moreover, extrusion allows for continuous production, which is vital in fast-paced markets. This process enables the design of complex shapes and profiles, catering to diverse applications. Reports highlight that businesses adopting extrusion technology see a 25% increase in production speed on average. Yet, some manufacturers may encounter maintenance issues or occasional downtime, impacting overall efficiency. This aspect necessitates regular training and monitoring to optimize operations.