In today's world, the materials we choose for our everyday products play a critical role in our lives, impacting everything from durability to aesthetics. Among these materials, ABS plastic stands out as a versatile and widely-used option. Known for its excellent strength-to-weight ratio, resistance to impact, and ease of fabrication, ABS plastic has become a go-to material in various applications ranging from consumer goods to automotive parts.

In this ultimate guide, we will delve deep into the benefits and practical uses of ABS plastic in everyday life. We will explore how this remarkable material not only enhances the functionality and longevity of products but also contributes to innovative design and manufacturing processes. By understanding the unique properties of ABS plastic, we can appreciate its significance in creating reliable and efficient solutions for modern living. Whether you're a consumer, a manufacturer, or simply curious about materials, this guide aims to provide valuable insights into how ABS plastic shapes our daily experiences.

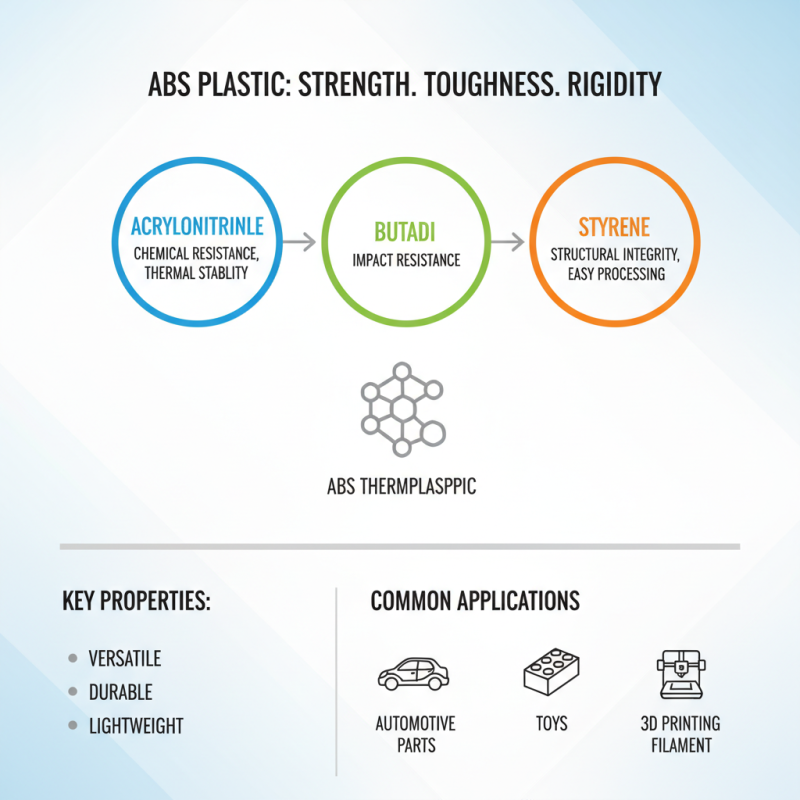

Acrylonitrile Butadiene Styrene, commonly known as ABS plastic, is a versatile thermoplastic that plays a significant role in various applications due to its unique properties. Comprising three primary components—acrylonitrile, butadiene, and styrene—ABS offers a balanced blend of strength, toughness, and rigidity. The acrylonitrile component contributes to chemical resistance and thermal stability, while butadiene imparts impact resistance, making the material resilient under stress. Styrene adds structural integrity and allows for easy processing.

The composition of ABS allows it to be molded into intricate shapes, making it ideal for manufacturing a wide array of products in everyday life. From automotive parts and electronic housings to household goods and toys, ABS plastic is prized for its durability and ease of fabrication. Its ability to withstand high temperatures and resist fatigue makes it suitable for both indoor and outdoor applications, thereby demonstrating its practicality and value in various sectors. Understanding these characteristics provides insight into why ABS plastic is a popular choice in modern manufacturing and design.

ABS plastic, or Acrylonitrile Butadiene Styrene, has emerged as a vital material in various everyday applications due to its impressive properties. One of the key benefits of ABS plastic is its exceptional impact resistance. According to a report by the Plastics Industry Association, ABS can withstand significant stress without cracking, making it an ideal choice for products that require durability, such as household appliances, automotive parts, and consumer electronics. This resilience ensures that items made from ABS can endure the rigors of daily use while maintaining their integrity and aesthetic appeal.

Another notable advantage of ABS plastic is its excellent machinability and versatility in manufacturing processes. It can be easily molded and shaped into complex forms, which allows for innovative designs in products ranging from toys to medical devices. The global market for ABS plastic is projected to reach over 10 million metric tons by 2025, as noted in a study by Research and Markets, highlighting its growing importance in various sectors. Additionally, the material can be finished with different textures and colors, making it a preferred choice for applications where aesthetics matter, such as in furniture and automotive interiors. The combination of these characteristics solidifies ABS plastic's position as a valuable material in everyday life, contributing to efficiency and style across multiple industries.

ABS plastic, or acrylonitrile-butadiene-styrene, is a versatile thermoplastic that is widely used in various household products due to its excellent strength, durability, and resistance to impact. One of the most common applications of ABS plastic can be found in everyday items such as toys. For example, many children’s toys are manufactured from ABS, making them not only safe for play but also able to withstand rough handling.

In addition to toys, ABS plastic is frequently utilized in kitchenware and appliances. Its heat resistance and toughness make it an ideal material for items such as dish racks, cutting boards, and storage containers. Moreover, ABS is often used in the manufacturing of electronic housings, like remote controls and small appliances, providing a lightweight yet sturdy structure that helps protect the internal components. This combination of properties ensures that ABS plastic is not only functional but also aesthetically pleasing, available in a variety of colors and finishes to match home décor.

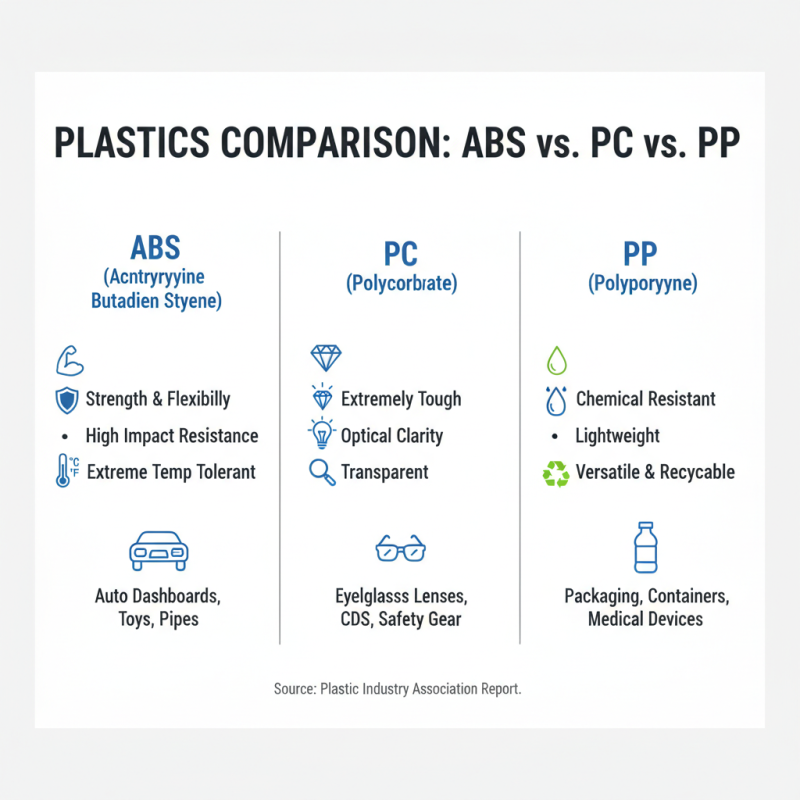

When comparing ABS plastic to other common plastics such as polycarbonate (PC) and polypropylene (PP), the unique attributes of ABS make it a preferred choice in various applications. ABS, or acrylonitrile butadiene styrene, combines strength and flexibility, offering impact resistance and toughness that are crucial for everyday products. According to a report by the Plastic Industry Association, ABS is often favored in the automotive sector for components like dashboards and bumpers due to its high resilience and ability to withstand extreme temperatures without deforming.

In contrast, while polycarbonate is known for its superior clarity and high strength, it tends to be more expensive and less readily available for some applications. Additionally, polycarbonate lacks the chemical resistance found in ABS, making ABS a better fit for household items like appliances and toys, where durability and safety are paramount. Similarly, polypropylene is lightweight and resistant to chemicals, but it does not match the structural integrity and aesthetic appeal of ABS, which is why ABS is frequently utilized in consumer electronics housings and construction materials. This comparative analysis underscores the advantages of ABS plastic, highlighting its pivotal role in various sectors where resilience and versatility are essential.

ABS plastic, or acrylonitrile-butadiene-styrene, is a commonly used material known for its durability and versatility. However, its environmental impact cannot be overlooked. The production of ABS plastic involves fossil fuels, which contribute to greenhouse gas emissions. Moreover, many plastic products have a short lifespan, leading to significant amounts of plastic waste in landfills and water bodies. It is essential to address these environmental considerations to mitigate the adverse effects associated with ABS plastic use.

Recycling ABS plastic is a viable solution to reduce its environmental footprint. The material is highly recyclable, and processes are in place that allow ABS products to be reprocessed and reused in various applications. This not only conserves resources but also minimizes waste. Many communities have implemented recycling programs specifically for plastics, including ABS, encouraging consumers to participate actively. Awareness of recycling practices can significantly enhance the sustainability of ABS plastic, turning a potentially harmful product into a resource for future use. By embracing recycling, we can help reduce the burden on the environment while still enjoying the benefits that ABS plastic offers in our daily lives.

| Aspect | Description |

|---|---|

| Material Type | Acrylonitrile Butadiene Styrene (ABS) |

| Key Benefits | Durability, impact resistance, and lightweight |

| Common Uses | Consumer electronics, automotive parts, and toys |

| Environmental Impact | Non-toxic, but not biodegradable |

| Recycling Information | Can be recycled, often used in 3D printing filament |

| End-of-Life Options | Recycling programs and waste-to-energy incineration |