In the ever-evolving landscape of modern manufacturing technologies, plastic extrusion stands out as a critical process that facilitates the production of a wide array of plastic products. According to a report by the Plastic Industry Association, the U.S. plastic industry accounted for over $400 billion in shipments in 2020, with a significant portion of this volume attributed to extrusion processes. This manufacturing technique enables the continuous production of complex shapes and profiles, making it indispensable for industries ranging from automotive to consumer goods.

The versatility of plastic extrusion not only enhances production efficiency but also plays a crucial role in sustainability efforts. Research indicates that incorporating recycled materials into the extrusion process can reduce energy consumption by up to 20% compared to traditional manufacturing methods. As industries increasingly prioritize sustainability, plastic extrusion is poised to remain at the forefront, driving innovation while addressing environmental concerns. By integrating advanced technologies such as automation and real-time monitoring, manufacturers can optimize the extrusion process, resulting in higher throughput and reduced waste.

As we delve deeper into the significance of plastic extrusion in modern manufacturing, it becomes evident that its ability to streamline production while fostering sustainable practices makes it an essential component for growth and competitiveness in today's market.

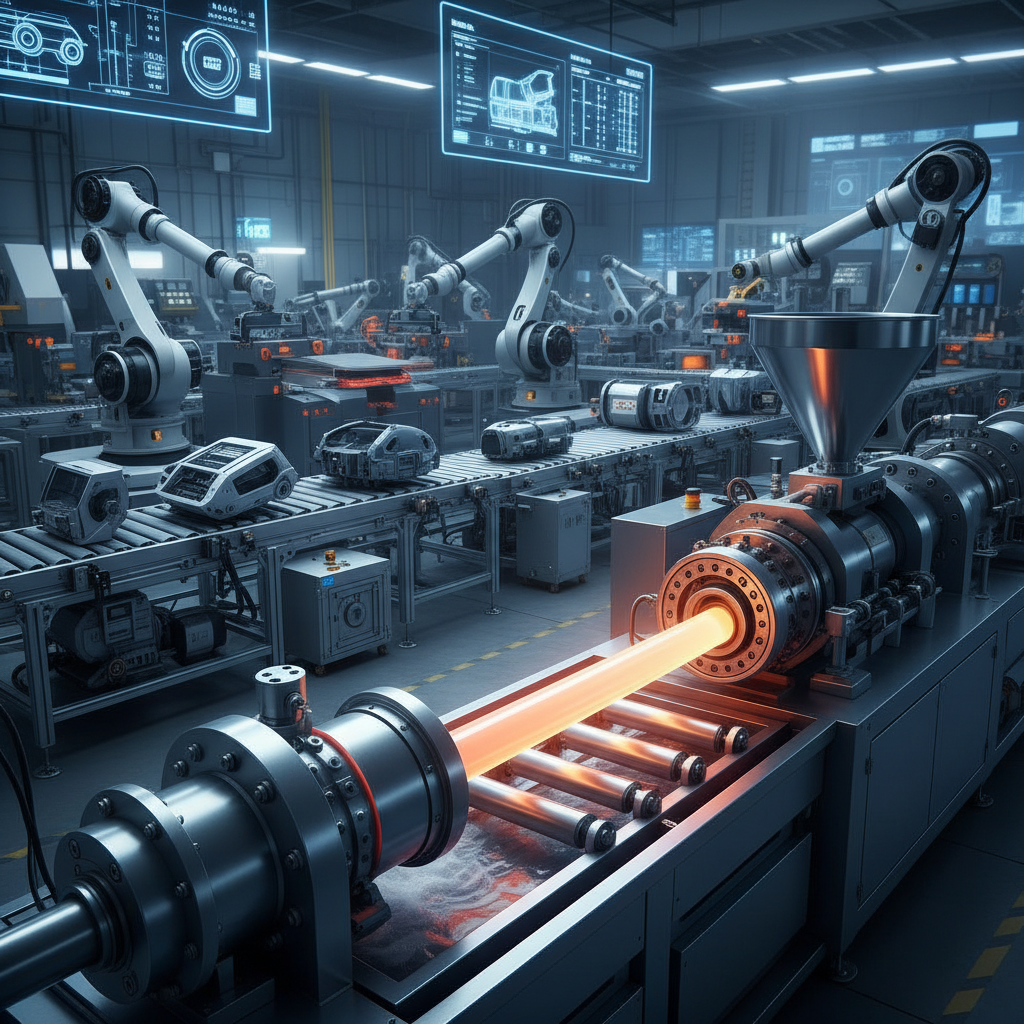

Plastic extrusion plays a vital role in modern manufacturing by streamlining production processes and enhancing efficiency. This technique involves melting plastic and forming it into a continuous profile, allowing manufacturers to produce consistent shapes and sizes with minimal waste. The precision of extrusion contributes significantly to supply chain optimization, enabling faster turnaround times and reduced costs. As industries continually seek to improve productivity, plastic extrusion stands out as a key technology driving advancement.

Tips for maximizing efficiency in plastic extrusion include regular maintenance of extrusion machinery to avoid downtime, and selecting the right polymer materials for specific applications to enhance product quality. Additionally, implementing real-time monitoring systems can help identify bottlenecks in the process, allowing for quick adjustments that improve overall throughput.

Moreover, investing in employee training on extrusion techniques and best practices can lead to better operation handling and a deeper understanding of the extrusion process. This knowledge empowers workers to troubleshoot issues effectively and contributes to a lean manufacturing environment, ultimately boosting output and sustaining competitive advantage in a rapidly evolving market.

Plastic extrusion technology is pivotal across various industries, significantly influencing their operational efficiency and product development. The automotive sector, for instance, leverages this technology for producing lightweight and durable components. The precision and versatility offered by plastic extrusion enable manufacturers to create complex shapes and dimensions, subsequently enhancing vehicle performance while adhering to stringent safety standards.

In the medical field, biodegradable materials like polyhydroxyalkanoates (PHA) are gaining traction, with applications ranging from biomedical implants to packaging. The global PHA market is projected to grow remarkably, driven by the increasing demand for sustainable and eco-friendly solutions. Industries recognize the benefits of using plastic extrusion to meet these needs, allowing the development of innovative products that align with environmental goals.

Tips: When considering plastic extrusion for your manufacturing process, focus on the specific requirements of your end products. Analyzing the material properties and operational parameters can lead to improved outcomes. Moreover, investing in advanced extrusion technology can aid in reducing waste and enhancing product quality, ultimately leading to better market competitiveness.

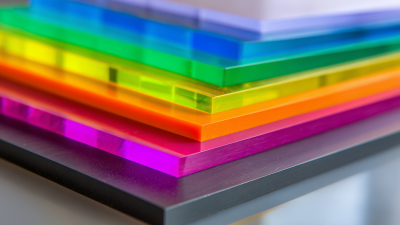

Plastic extrusion has evolved significantly with the advent of innovative materials and techniques, revolutionizing modern manufacturing technologies. The integration of advanced polymers, such as bio-based plastics and composites, has expanded the applications of extrusion beyond traditional uses. These materials not only enhance product performance but also contribute to sustainability by reducing environmental impact. Manufacturers are increasingly leveraging these innovations to create lightweight, durable products that meet the growing demands for efficiency and sustainability in various industries.

Among the modern techniques in plastic extrusion, the implementation of automation and smart manufacturing processes stands out. Automated systems allow for precise control over temperature and pressure, resulting in higher product quality and consistency. Additionally, techniques like co-extrusion and multi-layer extrusion enable the production of complex shapes and structures that would be challenging to achieve with conventional methods. The continuous development in extrusion technologies is paving the way for more customized solutions, thus making plastic extrusion an essential component of future manufacturing practices.

| Material Type | Extrusion Temperature (°C) | Applications | Advantages | Challenges |

|---|---|---|---|---|

| Polyethylene (PE) | 160-220 | Packaging, Containers | Low cost, Durability | Environmental concerns |

| Polyvinyl Chloride (PVC) | 160-210 | Pipes, Window Frames | Versatility, Chemical resistance | Brittleness at low temperatures |

| Polystyrene (PS) | 180-220 | Disposable Cutlery, Toys | Good insulation, Low cost | Fragility, Not recyclable |

| Acrylic (PMMA) | 200-220 | Display Cases, Signs | Transparency, Scratch resistance | Higher cost than other plastics |

| Polycarbonate (PC) | 260-300 | Safety Glasses, Electronics | Impact resistance, Lightweight | UV degradation over time |

Plastic extrusion plays a crucial role in modern manufacturing, particularly as industries increasingly prioritize sustainability.

The process of plastic extrusion allows for the creation of various products while minimizing waste and energy consumption.

To ensure environmentally friendly practices, manufacturers are exploring innovative methods such as using recycled materials and optimizing energy efficiency within the extrusion process.

Employing sustainable practices not only reduces the environmental footprint but also enhances the overall brand reputation.

Tips for sustainability in plastic extrusion include prioritizing the use of bio-based or recycled feedstocks, which can significantly reduce reliance on virgin plastics.

Additionally, implementing energy-efficient machinery and practices, such as regular maintenance and optimizing production schedules, can help lower energy consumption.

Collaboration with suppliers committed to sustainability can further enhance these efforts, ensuring that every stage of the supply chain aligns with eco-friendly objectives.

By fostering these sustainable practices, manufacturers can contribute to a more circular economy in the plastic industry.

Plastic extrusion has increasingly become a cornerstone of modern manufacturing technologies, reflecting the dynamic evolution of industrial processes. As manufacturers strive for efficiency and sustainability, the plastic extrusion method adapts to incorporate advanced materials and eco-friendly practices. The production of resin pellets, often the foundation for subsequent processes like injection molding and blow molding, illustrates how intrinsic plastic extrusion is to creating a variety of products. The versatility and cost-effectiveness of this technique enable industries to meet growing demands while minimizing waste and optimizing production cycles.

Looking ahead, future trends suggest that plastic extrusion will continue to evolve in alignment with technological advancements and market needs. Innovations in material science are leading to the development of new types of polymers and composites that can enhance the properties of extruded products. Furthermore, automation and digitalization in manufacturing are likely to streamline extrusion processes, increasing precision and reducing downtime. As industries push towards greater sustainability, the integration of recycled materials into extrusion methods will play a pivotal role in shaping the future landscape of manufacturing, emphasizing a circular economy.