When it comes to selecting materials for design and manufacturing projects, ABS plastic stands out as a versatile choice that balances durability and ease of use. According to Dr. Emily Chen, a leading materials scientist in the field of polymers, "ABS plastic's unique properties make it an ideal solution for a wide range of applications, from prototypes to final products." In this guide, we’ll explore the top tips for using ABS plastic effectively, ensuring that your projects not only meet design specifications but also enhance functionality and longevity.

ABS plastic is celebrated for its resilience and impact resistance, which makes it particularly suitable for both industrial and consumer products. As designers and engineers look to streamline their processes and improve product performance, understanding the nuances of working with this thermoplastic is crucial. Through practical advice and expert insights, we aim to equip you with the knowledge needed to make informed decisions when incorporating ABS plastic into your projects. Whether you're a seasoned professional or just starting in the industry, mastering these techniques will help you harness the full potential of ABS plastic.

ABS plastic, or acrylonitrile butadiene styrene, is a versatile thermoplastic that is widely used in various applications due to its remarkable properties. One of its most notable characteristics is its excellent impact resistance, making it an ideal choice for products that need to withstand rough handling or mechanical stress. Additionally, ABS exhibits strong chemical resistance, allowing it to endure exposure to a variety of substances without compromising its integrity. This combination of durability and resilience makes ABS plastic a go-to material in industries ranging from automotive to consumer electronics.

Another key benefit of using ABS plastic in your projects is its ease of processing. It can be easily molded and fabricated, enabling intricate designs and seamless production processes. This adaptability is complemented by its ability to be thermally molded, which allows for custom shapes that fit specific project requirements. Moreover, ABS can be easily painted, glued, or machined, providing further opportunities for customization and enhancing aesthetic appeal. These properties not only streamline the production process but also ensure that the final product meets the desired specifications and quality standards.

ABS plastic, known for its excellent strength-to-weight ratio and impact resistance, finds widespread application across various industries. In the automotive sector, for instance, ABS is utilized for manufacturing interior components, dashboards, and even certain body parts. According to a report by Transparency Market Research, the global ABS market in automotive applications was valued at approximately $5.8 billion in 2020 and is projected to expand due to the increasing demand for lightweight materials that contribute to fuel efficiency and enhance vehicle performance.

In the realm of consumer goods, ABS plastic is a staple in the production of items like toys, household products, and electronics enclosures. The global toy market, valued at around $90 billion in 2021, heavily relies on ABS due to its durable qualities and ability to be molded into complex shapes. Furthermore, the electronics industry benefits significantly from ABS's excellent thermal stability and electrical insulation properties, making it ideal for producing housings and components that can withstand rigorous use. Industry reports indicate that the ABS market in electronics is anticipated to achieve remarkable growth rates, driven by continuous innovation and demand for high-quality consumer electronics.

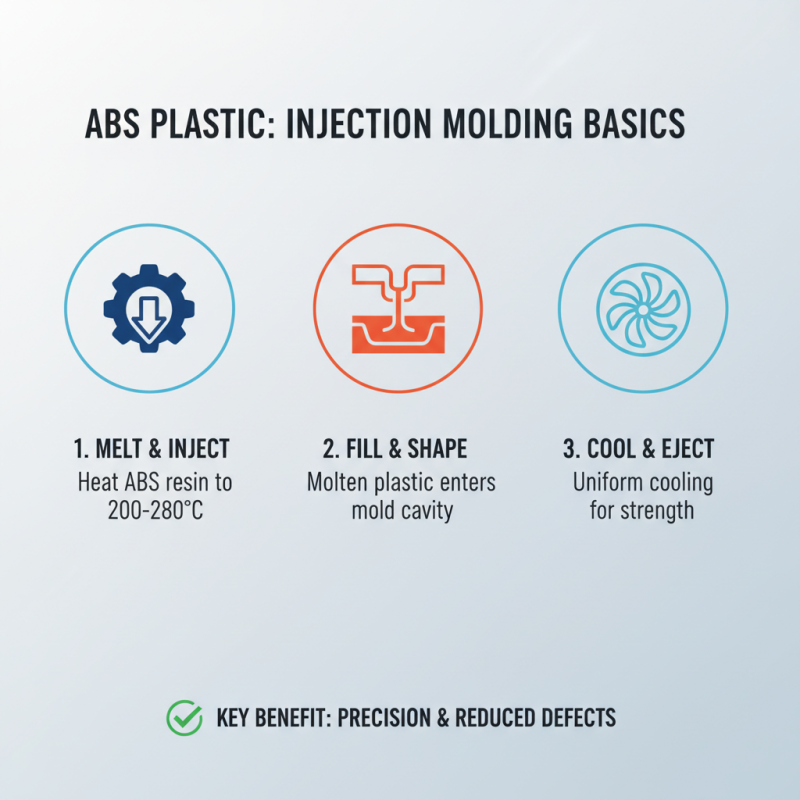

When it comes to processing ABS (Acrylonitrile Butadiene Styrene) plastic for your projects, understanding the optimal forming and molding techniques is crucial. One of the most common methods for shaping ABS is injection molding, which allows for precise control over both the mold design and the cooling process. This technique involves injecting molten ABS into a pre-designed mold, where it cools and solidifies into the desired shape. To achieve high-quality results, maintaining the appropriate temperature throughout the injection process is essential. Keeping the ABS resin at the right melting point ensures uniform flow into the mold, reducing defects such as warping or incomplete fills.

In addition to injection molding, other versatile processing techniques include extrusion and thermoforming. Extrusion is particularly effective for creating continuous lengths of ABS products, such as sheets or tubing. This method involves forcing melted ABS through a die, forming it into the desired cross-section as it cools and hardens. Similarly, thermoforming allows for shaping ABS sheets by heating them until soft and then forming them over a mold. Each technique has unique advantages, but selecting the right one depends on the complexity of the part, the production volume, and the specific characteristics desired in the final product. By mastering these processing techniques, you can enhance the functionality and aesthetic appeal of your ABS plastic applications.

When designing with ABS plastic, one of the best practices is to consider the material's thermal properties. ABS can be processed at a relatively low temperature, making it ideal for applications that require shaping without extensive energy consumption. However, it is important to avoid overheating, as excessive heat can lead to deformation or undesirable surface finishes. Utilizing appropriate cooling techniques during the molding process will ensure a smooth and well-defined final product.

Another crucial tip is to focus on the wall thickness and structural integrity of your design. ABS plastic is known for its impact resistance, but varying wall thickness can lead to weak points. Strive for uniform wall thickness wherever possible, as this enhances strength and durability while also ensuring even material distribution during production. Additionally, adding ribs or gussets in strategic locations can improve structural support without significantly increasing material usage.

Finally, consider the finishing options for your ABS projects. While ABS can be painted or coated, prepare the surface adequately to enhance adhesion. Sanding or applying a primer can help achieve a smoother finish. Don’t forget to test different adhesives for bonding ABS with other materials, as some may work better than others in specific applications. By following these best practices, you can fully leverage the advantages of ABS plastic in your designs while achieving high-quality results.

| Tip | Description | Best Practice |

|---|---|---|

| Consider Thermal Properties | Understand the heat resistance of ABS plastic for your applications. | Ensure components remain functional under expected temperature ranges. |

| Optimize Wall Thickness | Use optimal wall thickness to balance strength and weight. | Analyze design stress points to determine ideal thickness. |

| Choose Appropriate Finish | Select surface finishes to enhance aesthetics or functional properties. | Test finishes for durability and impact on function. |

| Utilize Proper Adhesives | Select adhesives that are compatible with ABS plastic. | Conduct bonding tests to ensure strong joints. |

| Consider Environmental Impact | Be mindful of the recyclability and environmental footprint of ABS. | Explore eco-friendly alternatives and recycling processes. |

When considering the use of ABS plastic in your projects, it's important to reflect on its sustainability aspects, particularly regarding recycling and environmental impact. ABS (Acrylonitrile Butadiene Styrene) is a versatile material widely used in various applications, but its production and disposal can have significant environmental implications. By prioritizing recycling and using responsibly sourced ABS, you can mitigate some of these impacts. When ABS products reach the end of their life cycle, they can often be recycled, which conserves resources and reduces landfill waste.

To use ABS plastic effectively, one key tip is to design your product with recyclability in mind. Aim to create components that can be easily disassembled to facilitate recycling. Additionally, consider using post-consumer or post-industrial recycled ABS. This not only reduces the need for virgin materials but also decreases the overall carbon footprint associated with your project.

Another crucial tip is to educate yourself about local recycling guidelines for ABS plastic. Knowing where and how to recycle can ensure that your project's waste is managed responsibly. It’s equally important to assess the potential environmental impact of your project during the design phase, taking into account the life span of the ABS products and how they contribute to a circular economy. By adopting these practices, you can enhance the sustainability of your ABS plastic projects while still achieving your design goals.