In recent years, ABS sheets have gained immense popularity across various industries due to their remarkable versatility and exceptional performance. These lightweight yet durable materials offer significant advantages that make them ideal for a wide range of applications, from construction and design to prototyping and manufacturing. Utilizing ABS sheets in your projects can lead to enhanced efficiency and creative possibilities, along with significant cost savings.

One of the standout features of ABS sheet is its impressive strength-to-weight ratio, which makes it an attractive alternative to traditional materials. This robust composition not only ensures durability but also facilitates ease of handling and installation. Furthermore, ABS sheets can be easily thermoformed and fabricated, allowing designers and engineers to bring their concepts to life with minimal effort. As industries progressively embrace sustainable practices, the recyclability of ABS sheets further positions them as a forward-thinking choice in responsible project planning. Overall, exploring the benefits of ABS sheets can unlock new avenues for innovation and functionality in various projects.

ABS (Acrylonitrile Butadiene Styrene) sheets offer a multitude of advantages in construction and manufacturing projects. Their exceptional durability and impact resistance make them an ideal material for environments that demand robustness. According to a report by the Plastic Industry Association, the use of ABS in construction has increased by approximately 15% over the past five years, primarily due to its lightweight nature and strength-to-weight ratio. This allows for easier handling, reduced transportation costs, and efficient installation processes.

In addition, ABS sheets exhibit excellent resistance to chemicals and environmental factors, making them suitable for a wide range of applications, from automotive components to household fixtures. A study published in the Journal of Polymer Science highlighted that ABS demonstrates a resistance to corrosion and UV radiation, which extends the lifespan of projects and reduces long-term maintenance costs. Furthermore, their ability to be easily molded and fabricated allows for greater design flexibility, which is crucial in innovative manufacturing processes where precision and customization are key. Thus, leveraging ABS sheets enhances both the quality and efficiency of construction and manufacturing endeavors.

| Benefit | Description | Application Areas |

|---|---|---|

| High Impact Resistance | ABS sheets can withstand heavy impacts without cracking or breaking. | Manufacturing of durable products, automotive parts, and furniture. |

| Lightweight | They are significantly lighter than many other materials, making them easy to transport and handle. | Construction and DIY projects. |

| Weather Resistant | ABS sheets resist moisture and UV light, ensuring longevity outdoors. | Outdoor signage and exterior construction applications. |

| Easy to Fabricate | ABS can be easily cut, shaped, and joined using various techniques. | Custom fabrication in prototyping and manufacturing. |

| Excellent Chemical Resistance | Resists various chemicals, making it suitable for industrial applications. | Chemical storage tanks and laboratory equipment. |

| Good Aesthetic Qualities | Can be produced in various colors and finishes, enhancing visual appeal. | Interior design and consumer products. |

| Cost-Effective | Relatively inexpensive compared to other engineering plastics. | Mass production of components and parts. |

| Sound Dampening | Acts as an effective barrier to sound transmission. | Noise reduction in housing and commercial settings. |

| Excellent Thermal Properties | Retains its shape and strength even under high temperatures. | Electrical housings and automotive applications. |

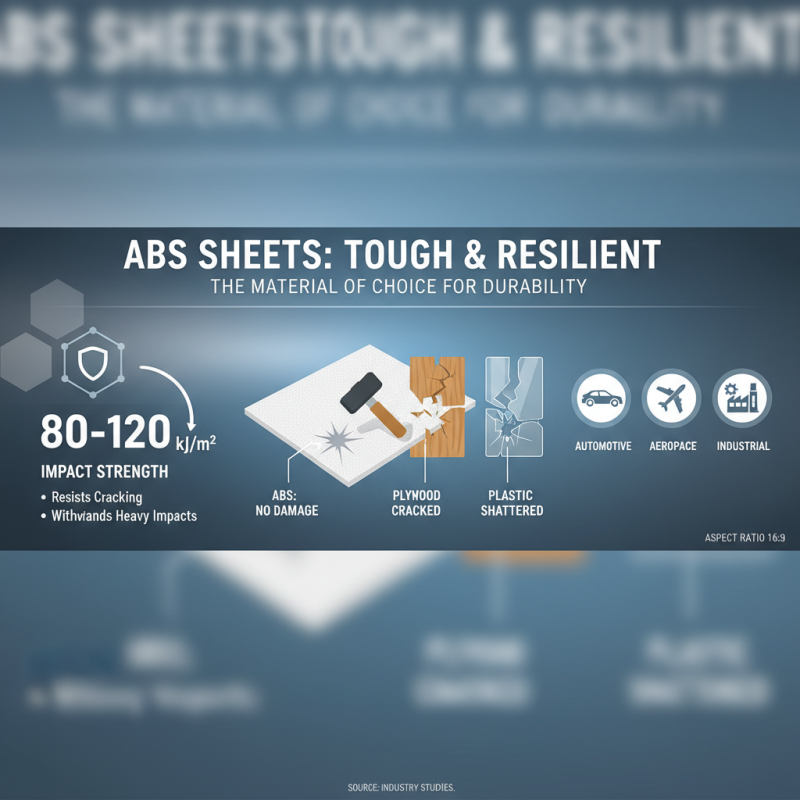

ABS (Acrylonitrile Butadiene Styrene) sheets have become increasingly popular in various applications due to their outstanding durability and impact resistance. According to industry studies, ABS sheets boast an impressive impact strength of approximately 80-120 kJ/m², making them significantly more resilient compared to traditional materials like plywood and some plastics. This inherent toughness allows ABS sheets to withstand heavy impacts without cracking or breaking, further enhancing their viability in high-stress environments such as automotive, aerospace, and industrial settings.

Moreover, ABS sheets excel in harsh environmental conditions, demonstrating excellent resistance to heat, chemicals, and moisture. Research from the American Society for Testing and Materials (ASTM) indicates that ABS exhibits high dimensional stability under varying temperatures, maintaining its integrity and structural strength from -20°C to 80°C. Such properties not only ensure the longevity of projects utilizing ABS sheets but also contribute to reduced maintenance costs over time. This combination of durability and adaptability makes ABS sheets a top choice for designers and engineers looking for reliable materials in both commercial and residential applications.

When it comes to budget-conscious projects, the cost-effectiveness of ABS sheets stands out as a significant advantage. These sheets are not only affordable but also offer a durable and versatile alternative to traditional materials. Their lightweight nature reduces transportation costs, and their easy handling means less time and labor is required during installation. This combination of attributes helps keep project expenses low without compromising on quality.

Additionally, the longevity and resistance to environmental factors make ABS sheets a wise investment. Unlike materials that may require frequent replacement or maintenance, ABS sheets are designed to withstand wear and tear, ensuring that your project remains intact over time. This durability translates into lower lifecycle costs, making ABS sheets an ideal choice for those looking to maximize their budget while still achieving high-quality results. With their wide range of applications, from prototyping to final products, the value derived from using ABS sheets easily surpasses the initial cost, ensuring that projects meet both financial and aesthetic goals.

ABS sheets, known for their robust properties, have established a significant presence across multiple industries due to their versatility and adaptability. In the automotive sector, for example, ABS sheets offer excellent impact resistance and rigidity, making them ideal for manufacturing interior components, dashboards, and even exterior parts. According to a report by Smithers Pira, the global demand for ABS in automotive applications is expected to reach approximately 1.2 million tons by 2024, driven by the increasing emphasis on lightweight materials to enhance fuel efficiency.

In the realm of consumer electronics, ABS sheets are widely used in the production of housings and enclosures due to their excellent thermal stability and aesthetic appeal. The International Data Corporation (IDC) predicts that the market for electronic devices will continue to expand, with ABS sheets playing a crucial role in meeting the industry's needs for reliable and customizable materials. Furthermore, with the increasing demand for sustainable practices, many industries are now exploring the reusability and recyclability of ABS sheets, which is expected to positively influence the market dynamics in construction, signage, and medical applications. The flexibility of ABS sheets allows manufacturers to innovate and create tailored solutions, proving essential in a rapidly evolving market landscape.

ABS sheets have gained popularity in various design projects due to their remarkable ease of fabrication and modification. Designers appreciate the material's lightweight nature, which allows for effortless handling and shaping. When it comes to cutting and machining, ABS sheets can be easily sawn, drilled, and routed, enabling intricate designs and custom dimensions to suit specific project needs. This flexibility not only streamlines the fabrication process but also reduces the time and effort involved in getting a project off the ground.

Moreover, the thermoplasticity of ABS sheets means that they can be heat-formed into a variety of shapes, offering even more design possibilities. When heated, these sheets can be molded to create complex forms, allowing designers to push the boundaries of their creativity. Additionally, the ability to weld and bond ABS with adhesives further enhances its adaptability. This means that designers can easily make modifications on-site, ensuring that any adjustments can be seamlessly integrated into the overall design without compromising structural integrity. As a result, ABS sheets stand out as a versatile choice for those looking to innovate and execute their visions effortlessly.