Choosing the right plastic roll for your packaging needs is essential in today’s dynamic business environment, where packaging plays a critical role in product preservation and branding. According to a recent report by MarketsandMarkets, the global plastic packaging market is projected to reach USD toujours important d'utiliser des matériaux adéquats pour garantir la qualité et la sécurité des produits. With a variety of plastic roll options available, understanding their unique properties—such as barrier performance, thickness, and flexibility—is crucial. A well-informed choice not only enhances product protection but can also lead to cost savings and improved sustainability. Therefore, whether you are packaging food, pharmaceuticals, or consumer goods, selecting the right plastic roll can significantly impact your operations and market success.

When selecting the right plastic roll for your packaging needs, it is essential to understand the different types available and their specific applications. Plastic rolls are manufactured from various materials, each offering distinct properties tailored for specific functions. For instance, polyethylene (PE) rolls are widely favored for their moisture resistance and flexibility, making them ideal for food packaging and perishable goods. According to a recent market research report, the demand for PE plastic packaging is projected to grow at a compound annual growth rate (CAGR) of 4.5% through 2025, reflecting its widespread usage and critical role in the packaging industry.

In addition to polyethylene, polyvinyl chloride (PVC) and polypropylene (PP) rolls also play significant roles in packaging solutions. PVC rolls are known for their durability and clarity, making them a popular choice for retail packaging, while PP rolls are praised for their strength and resistance to chemical exposure, which makes them suitable for industrial applications. Industry data suggests that the polypropylene market alone is expected to exceed $100 billion by 2026, indicating its increasing prominence in packaging. Understanding these material characteristics will help businesses select the most suitable plastic roll for their unique packaging requirements, ensuring efficiency and product safety.

When selecting plastic rolls for packaging, several key factors must be taken into consideration to ensure they meet your specific needs. First and foremost, understanding the type of plastic material is crucial. Different plastics, such as polyethylene or polypropylene, have distinct properties regarding durability, clarity, and flexibility. Think about the conditions your packaging will face—will it be exposed to moisture, extreme temperatures, or UV light? Selecting a material that withstands these factors will greatly enhance the effectiveness of your packaging solution.

Another important consideration is the roll size and thickness. The dimensions of the roll should align with your packaging equipment and the products you intend to package. A thicker roll may provide more protection but could also result in increased costs. Conversely, a thinner roll may save money but could compromise product safety. Additionally, consider the environmental impact of the plastic you choose. Opting for recyclable or biodegradable options can not only support sustainability but also appeal to environmentally conscious consumers. By evaluating these factors carefully, you can choose the right plastic roll that best fits your packaging requirements.

When selecting the appropriate plastic roll for your packaging requirements, cost-effectiveness is a pivotal criterion to consider. Various options are available, each presenting its own advantages and price points. For instance, low-density polyethylene (LDPE) rolls are often favored for their flexibility and affordability. They serve well in light-duty applications and can significantly reduce expenses when used in bulk. Conversely, higher-grade materials like polypropylene (BOPP) may come at a premium but offer superior strength and clarity, making them ideal for products that prioritize visibility and protection.

Moreover, it’s essential to evaluate the total cost of ownership, which includes not just the purchase price but also factors such as durability, waste management, and transportation costs. Some plastic rolls can yield more product per roll, enhancing their cost-effectiveness over time by reducing the frequency of replacement. Selecting the right plastic roll entails balancing initial costs with long-term performance and sustainability goals, ensuring that the chosen option aligns not only with your budget but also with your packaging needs.

| Plastic Type | Thickness (microns) | Cost per Meter ($) | Stretch Ability (%) | Best Use Cases |

|---|---|---|---|---|

| LDPE (Low-Density Polyethylene) | 20 | 0.05 | 300 | Food Packaging, Bags |

| HDPE (High-Density Polyethylene) | 30 | 0.06 | 200 | Industrial Packaging, Bottles |

| PVC (Polyvinyl Chloride) | 40 | 0.08 | 150 | Wraps, Containers |

| PP (Polypropylene) | 35 | 0.07 | 250 | Food Containers, Packaging |

| PET (Polyethylene Terephthalate) | 25 | 0.09 | 230 | Bottles, Food Packaging |

When selecting a plastic roll for your packaging needs, it's vital to consider key features that enhance functionality and efficiency. First, the thickness of the plastic roll plays a crucial role in durability. A thicker material can withstand various pressures during transportation, reducing the likelihood of tears or punctures. When choosing a thickness, consider the weight and fragility of your products to ensure adequate protection.

Another important feature is the transparency of the plastic roll. High clarity allows for easy visibility of the packaged product, making it ideal for retail settings. Additionally, a transparent roll can help maintain brand aesthetics while ensuring that the product stands out to consumers.

**Tip:** Always assess the environmental impact of the plastic you choose. Opting for recyclable or biodegradable options can enhance your brand’s sustainability profile and cater to eco-conscious customers.

Lastly, consider the roll's width and length, as these dimensions need to align with your packaging machinery and storage space. Choosing the right size reduces waste and improves efficiency, ensuring that you can seamlessly integrate the rolls into your production process.

**Tip:** Evaluate the compatibility of the plastic roll with your pre-existing packing equipment to avoid disruptions in your operations.

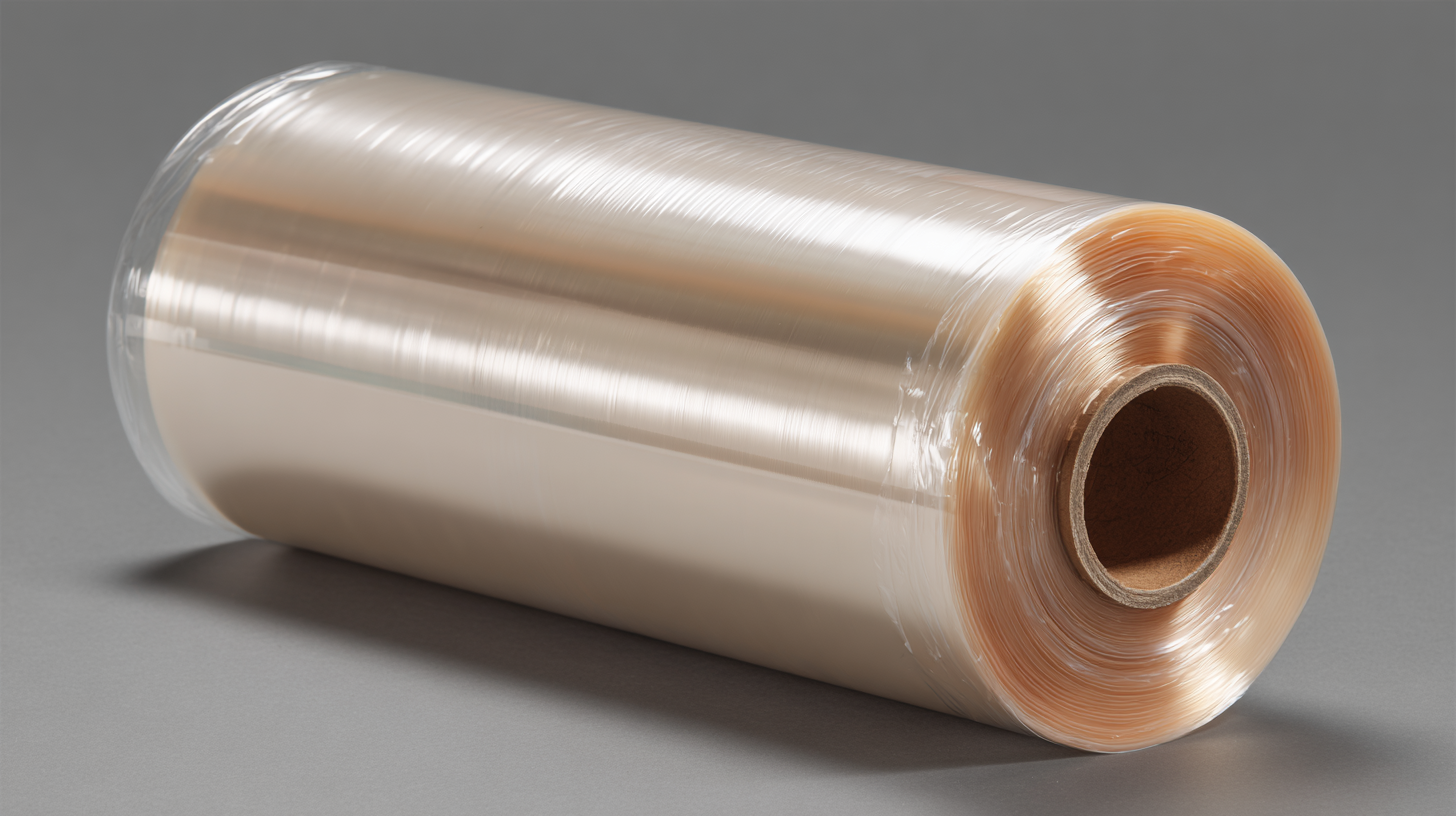

When utilizing plastic rolls for packaging, maximizing efficiency begins with understanding the specific requirements of your products. Choosing the right type of plastic roll, such as stretch film, shrink wrap, or poly bags, is crucial. Each material has unique properties suited for different packaging contexts. For instance, stretch film is ideal for securing pallet loads during transport, while shrink wrap provides a tight seal around products, enhancing protection and presentation. Tailoring the type of plastic roll to the characteristics of your items ensures that they arrive safely to their destination while minimizing waste.

In addition to selecting the appropriate plastic roll, implementing best practices during the packaging process can significantly enhance efficiency. Ensuring that the packaging area is organized and that the necessary tools, such as dispensers and cutting equipment, are readily available can streamline operations. Training staff on proper techniques for wrapping and sealing products not only speeds up the process but also improves the overall quality of the packaging. Regularly assessing and adjusting the packaging methods based on feedback and performance metrics will help maintain high efficiency and adapt to any changing needs in the production line.