Vacuum molding is revolutionizing the way custom plastic parts are produced, offering manufacturers a versatile and cost-effective solution. This process, which involves creating a mold by vacuum suction, allows for the production of complex designs with high precision and optimal material usage. As businesses increasingly seek tailored solutions that meet specific requirements, vacuum molding has emerged as the preferred choice for various industries, including automotive, consumer products, and medical devices.

One significant advantage of vacuum molding is its ability to produce parts quickly and efficiently, making it ideal for both small and large production runs. This method not only reduces time to market but also minimizes waste, as it utilizes less material compared to traditional injection molding techniques. Additionally, vacuum molding accommodates a wide range of thermoplastic materials, enhancing the customization possibilities for designers.

Ultimately, the growing demand for high-quality, customized plastic components makes vacuum molding an indispensable process in modern manufacturing. By leveraging its advantages, businesses can achieve greater flexibility, cost savings, and innovation, affirming vacuum molding as the superior choice for custom plastic parts production.

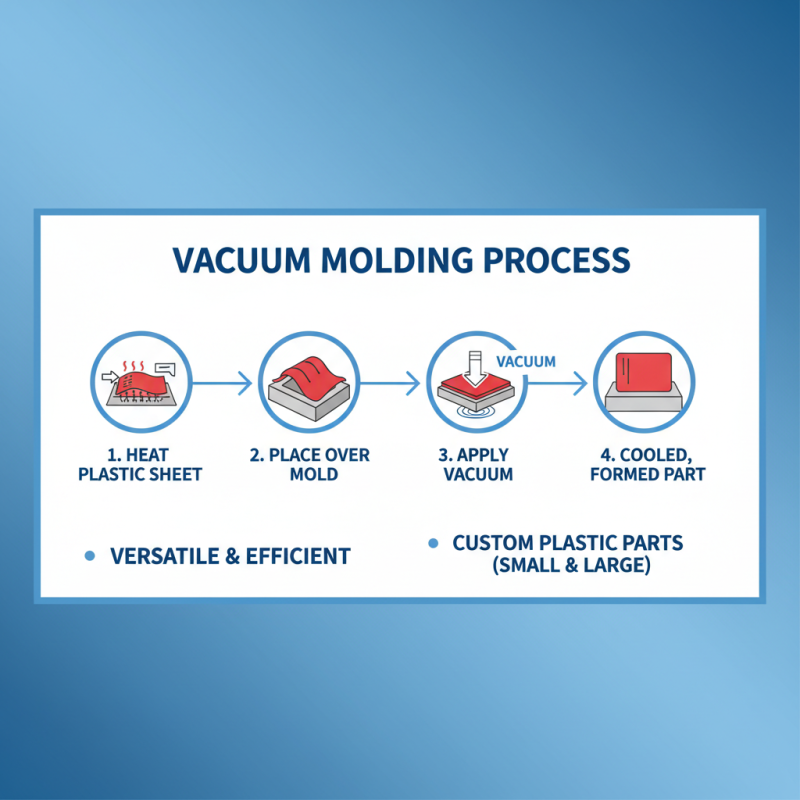

Vacuum molding is a versatile and efficient process utilized in the production of custom plastic parts. This method involves heating a thermoplastic sheet until soft and pliable, then placing it over a mold. By creating a vacuum between the mold and the plastic, the material is drawn tightly against the mold's surface, ensuring a precise fit and intricate detail in the final product. This process is especially beneficial for producing both small and large runs of parts, making it an excellent choice for various applications across industries.

One of the key advantages of vacuum molding is its ability to create lightweight yet durable components. This process allows for the fabrication of complex shapes that are both strong and aesthetically pleasing. Moreover, with faster cycle times and lower tooling costs compared to other methods such as injection molding, manufacturers find vacuum molding an economically viable option for custom production needs. Whether it’s prototyping or full-scale production, vacuum molding offers flexibility and efficiency, making it a preferred technique for those seeking quality and precision in custom plastic parts.

Vacuum molding has emerged as a preferred method for producing custom plastic parts, primarily due to its numerous advantages over traditional manufacturing techniques like injection molding or blow molding. One of the standout benefits is the significant cost-effectiveness in low to medium production runs. According to a report by the Association for Manufacturing Technology, vacuum molding can reduce tooling costs by up to 70% compared to traditional methods, making it an excellent option for startups or businesses needing customized parts but lacking the budget for high-volume production molds.

Another critical advantage is the shorter lead time. Vacuum molding allows for quicker turnaround from design to production. The process involves creating a mold from a master pattern that can be fabricated in a matter of days, not weeks. This rapid prototyping capability empowers manufacturers to test designs and iterate quickly, ultimately speeding up the product development cycle. Industry experts emphasize that this agility can provide a competitive edge, particularly in sectors where time-to-market is essential.

Tips: When considering vacuum molding, pay attention to the selection of materials. Some materials can enhance the part's performance and durability, providing advantages in specific applications. Additionally, ensure detailed communication of your design specifications with the manufacturer. Clear guidelines can minimize errors and accelerate the production process, ensuring that the final product meets your expectations.

Vacuum molding is a favored method for custom plastic parts production due to its versatility and efficiency. A critical aspect that influences the quality of the final products is the choice of materials. Various thermoplastics such as ABS, polycarbonate, and polypropylene offer distinct properties that can enhance the structural integrity, aesthetic appeal, and functional performance of the molded parts. According to a report by the Plastics Industry Association, materials like ABS contribute to a higher impact resistance and surface finish, making them suitable for applications ranging from automotive components to consumer goods. Conversely, polycarbonate’s exceptional strength and thermal resistance make it ideal for protective housings and medical devices.

When selecting materials for vacuum molding, it is essential to consider the intended application and environmental factors. High-performance materials may incur higher costs, but they can provide significant long-term benefits, including durability and reduced maintenance. Additionally, custom blends can be formulated to balance cost and performance, ensuring that the final product meets specific requirements without overshooting budget constraints.

**Tip:** Always conduct preliminary tests with different materials before final production. This approach allows you to assess performance attributes such as flexibility and strength, ensuring the chosen material aligns perfectly with your product's demands. Furthermore, collaborating with suppliers who understand the intricacies of material properties can lead to innovative custom solutions tailored to your needs.

Vacuum molding has emerged as a game-changer in the production of custom plastic parts, primarily due to its impressive cost efficiency. Unlike injection molding, which requires extensive tooling and setup costs, vacuum molding allows for quicker mold creation using less expensive materials. This results in significantly reduced initial investment, making it an ideal choice for small to medium production runs. A data-driven analysis shows that the lower overhead associated with vacuum molding not only shortens lead times but also decreases per-unit costs, which is crucial for companies looking to maximize their budgets.

When considering vacuum molding for your next project, one tip is to evaluate the complexity of your design. Simpler designs typically benefit the most from vacuum molding processes, allowing for faster production without compromising on quality. Additionally, collaborating closely with manufacturers during the design phase can lead to optimized mold designs that reduce material waste and production time further, translating to even greater savings. Another useful tip is to leverage prototypes. Producing a prototype through vacuum molding can provide vital insights into the design and functionality of parts before committing to larger-scale production, ensuring that potential issues are addressed upfront.

Vacuum molding technology has become increasingly vital across various sectors due to its unique advantages in producing custom plastic parts. Industries such as automotive, aerospace, healthcare, and consumer goods heavily rely on vacuum molding for creating prototypes and low- to medium-volume production parts. The automotive industry, for instance, benefits significantly from vacuum molding, as it allows for the rapid production of lightweight components that enhance fuel efficiency. According to a recent report by MarketsandMarkets, the demand for vacuum molded products in the automotive sector is projected to exceed USD 2 billion by 2025, driven by the growing need for customization and rapid production cycles.

In healthcare, vacuum molding plays a crucial role in creating custom packaging solutions and medical device housings. The ability to mold intricate designs with precision helps manufacturers meet stringent regulatory requirements while improving patient safety and comfort. A study conducted by Smithers Pira indicates that the medical packaging market is expected to grow at a CAGR of 6.6% through 2024, with vacuum-formed packaging solutions becoming increasingly popular due to their cost-effectiveness and efficiency. Furthermore, the consumer goods industry utilizes vacuum molding to produce a variety of products ranging from containers to electronic enclosures, with the global plastic packaging market projected to reach USD 500 billion by 2027, highlighting the technology's pervasive influence across multiple applications.

| Application | Industry | Material Used | Production Time (Days) |

|---|---|---|---|

| Consumer Electronics Housings | Electronics | ABS Plastic | 15 |

| Medical Device Components | Medical | Polycarbonate | 10 |

| Automotive Interior Parts | Automotive | PVC | 20 |

| Retail Display Cases | Retail | Acrylic | 12 |

| Prototype Models | Manufacturing | Nylon | 8 |