HDPE plastic sheets have emerged as a versatile material across various industries, driven by their unique properties such as high impact resistance, chemical stability, and moisture resistance. According to a recent report by Grand View Research, the global demand for HDPE (high-density polyethylene) is projected to reach 79.79 million tons by 2027, underscoring its growing significance. Beyond traditional applications in packaging and containers, HDPE plastic sheets are increasingly utilized in innovative areas such as construction, automotive, and healthcare, where durability and reliability are paramount. This exploration of HDPE plastic sheets reveals not only their conventional uses but also highlights unexpected applications that are reshaping industry practices. By delving into these diverse applications, organizations can harness the full potential of HDPE plastic sheets, optimizing their processes and enhancing sustainability.

HDPE (High-Density Polyethylene) plastic sheets are becoming increasingly popular in home improvement projects due to their durability and versatility. Often overlooked, these sheets can serve various purposes beyond traditional uses. For instance, they can be employed as impact-resistant surfaces for countertops in craft rooms or not only enhance aesthetics but also add protective qualities to kitchen designs. Moreover, HDPE sheets are low maintenance, making them ideal for outdoor furniture or garden beds where exposure to the elements is a concern.

**Tips for Using HDPE Plastic Sheets:** When considering HDPE for your next home project, ensure you select the right thickness for your specific needs. Thicker sheets offer better durability, while thinner ones might suffice for lighter applications. Remember to use appropriate adhesive or fasteners, as HDPE can be slippery; a textured surface could greatly enhance grip. Additionally, consider cutting sheets with a fine-tooth saw to prevent chipping, ensuring a clean finish for your DIY endeavors.

High-Density Polyethylene (HDPE) plastic sheets have emerged as a go-to material for creating outdoor furniture and décor, thanks to their exceptional durability and resistance to weather elements. According to a report by the American Society for Testing and Materials (ASTM), HDPE can withstand temperatures ranging from -40°F to 120°F, making it ideal for outdoor applications where traditional materials may falter. With the potential to last over 50 years, HDPE furniture stands out not only for its longevity but also for requiring minimal maintenance, a critical factor for busy households looking to enhance their outdoor spaces.

High-Density Polyethylene (HDPE) plastic sheets have emerged as a go-to material for creating outdoor furniture and décor, thanks to their exceptional durability and resistance to weather elements. According to a report by the American Society for Testing and Materials (ASTM), HDPE can withstand temperatures ranging from -40°F to 120°F, making it ideal for outdoor applications where traditional materials may falter. With the potential to last over 50 years, HDPE furniture stands out not only for its longevity but also for requiring minimal maintenance, a critical factor for busy households looking to enhance their outdoor spaces.

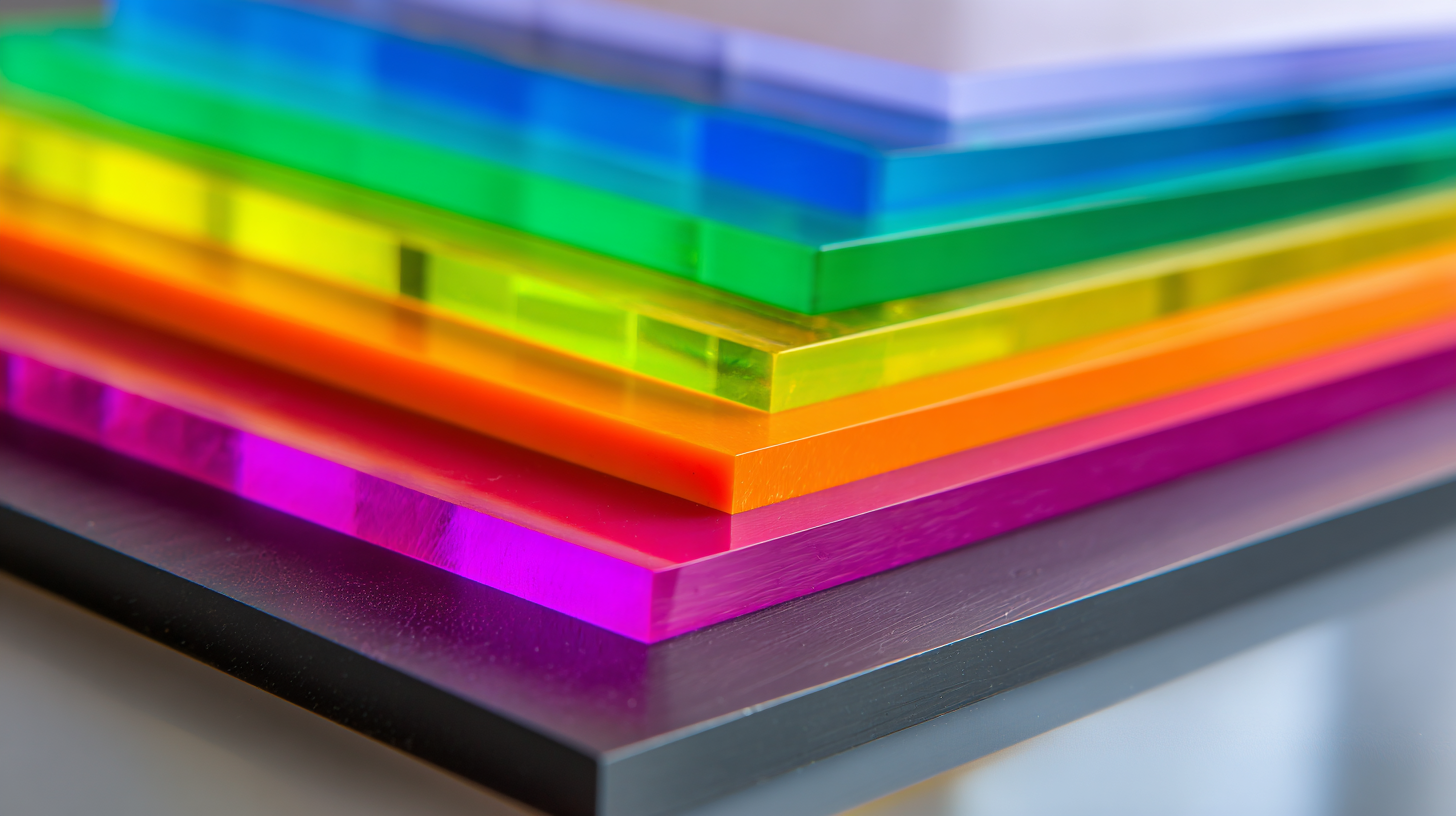

In addition to its practical benefits, HDPE offers remarkable versatility in design. It can be molded into various shapes and colors, allowing for highly customizable outdoor décor options. A study published by the Plastics Industry Association indicates that the global market for outdoor furniture made from sustainable materials, including HDPE, is projected to reach $5.3 billion by 2026. As consumers increasingly prioritize eco-friendly products, the ability of HDPE to be recycled and repurposed adds to its appeal, setting the stage for innovative creative solutions in outdoor furniture design that balances aesthetics with environmental responsibility.

High-Density Polyethylene (HDPE) plastic sheets are often recognized for their durability and versatility, but their role in promoting sustainable practices is equally significant. HDPE is a highly recyclable material, which means that products made from it can be reprocessed and reused multiple times, reducing the need for new raw materials. Additionally, HDPE sheets are used in various environmental applications, including liners for landfills and ponds, due to their excellent resistance to chemicals and moisture. This makes them an ideal choice for waste containment and water management solutions.

Tips: When selecting HDPE sheets for your projects, consider their thickness and density, as these factors can greatly influence their performance in various applications. If you're looking for eco-friendly options, prioritize using recycled HDPE, which can significantly cut down on carbon emissions and energy consumption during production.

As the HDPE pipes market is projected to reach USD 25.68 billion by 2029, it is clear that the demand for sustainable materials will continue to grow. Companies embracing eco-friendly practices through the use of HDPE not only contribute to environmental conservation but also stand to benefit economically in a market increasingly focused on sustainability.

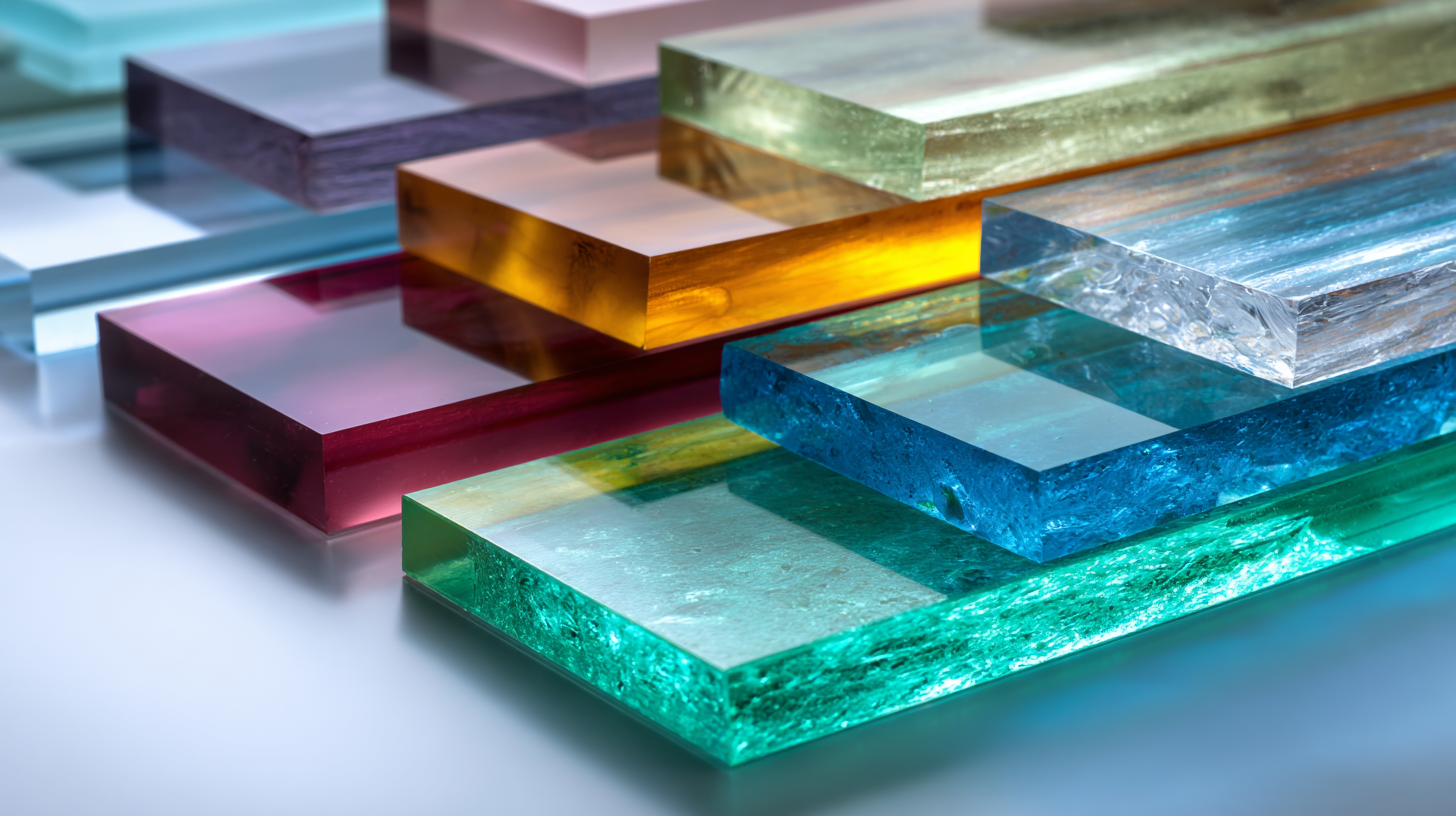

High-Density Polyethylene (HDPE) sheets are increasingly recognized for their adaptability across various industrial applications. While many are familiar with their use in packaging and construction, HDPE sheets find crucial roles in sectors such as agriculture, automotive, and even marine industries. According to a report from MarketsandMarkets, the global HDPE market is projected to grow from $68.3 billion in 2020 to $95.1 billion by 2025, with significant contributions from these lesser-known applications.

In agriculture, HDPE sheets serve important functions in the creation of greenhouse film, water reservoirs, and lining ponds. Their resistance to ultraviolet radiation and moisture makes them ideal for enhancing crop yield while reducing water usage. Additionally, the automotive industry utilizes HDPE sheets in various components, including fuel tanks and interior parts, which can withstand high impacts and resist chemical breakdown. A report by Grand View Research suggests that the automotive segment is expected to see substantial growth due to the increasing demand for lightweight materials that contribute to fuel efficiency.

Moreover, HDPE sheets are emerging as a popular choice for marine applications, including boatbuilding and dock construction, owing to their corrosion resistance and durability in saltwater environments. As industries continue to innovate, the versatility of HDPE sheets presents opportunities that go beyond conventional uses, paving the way for more sustainable and efficient practices across multiple sectors.

HDPE plastic sheets, renowned for their durability and versatility, have found intriguing applications in creative and artistic projects. Artists and designers are increasingly incorporating HDPE into their work, exploiting its unique properties such as lightweight structure, resistance to chemicals, and recyclability. This material can be transformed into a variety of artistic expressions, from sculptural installations to functional art pieces, enabling creators to push the boundaries of traditional mediums.

For example, HDPE sheets can be easily dyed and shaped, making them ideal for large-scale outdoor sculptures that need to withstand harsh environmental conditions. Additionally, their smooth surface allows for vibrant color applications, enhancing visual appeal. Artists are also experimenting with HDPE in mixed media projects, pairing it with other materials to create unexpected textures and effects. The possibilities are endless, inviting artists to innovate and redefine their craft while contributing to a more sustainable art practice.

| Application Area | Description | Benefits | Examples of Use |

|---|---|---|---|

| Art Installations | HDPE sheets are used to create large-scale visual art pieces, providing a durable and weather-resistant medium. | Lightweight, versatile, and resistant to moisture. | Sculptures, wall-mounted art, and outdoor exhibits. |

| Educational Projects | Use in schools for artistic and educational purposes, encouraging creativity and practical learning. | Safe for children, easy to work with, and long-lasting. | Classroom art projects, science displays, and building models. |

| DIY Projects | Ideal for crafting customized items at home, ranging from decorations to functional objects. | Cost-effective, easily cut and shaped, and available in various colors. | Custom signs, garden art, and furniture accents. |

| Theater Sets | Used in creating lightweight and durable stage props and backdrops. | Lightweight, easy to paint, and easy to manipulate on stage. | Backdrops for plays, props for performances, and interactive installations. |

| Community Art Projects | Facilitates group art initiatives that promote community engagement and expression. | Encourages collaboration and creativity within the community. | Murals, community sculptures, and public art displays. |